+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Composite materials for railings

Composite materials for railings

Composite railings offer a durable, low-maintenance alternative to wood or metal. Composite rails for decking provide weather resistance and aesthetic appeal, perfect for outdoor spaces. Similarly, a composite rail fence combines strength and longevity, making it ideal for residential and commercial use.

Composite materials for railings

Composite railings offer a durable, low-maintenance alternative to wood or metal. Composite rails for decking provide weather resistance and aesthetic appeal, perfect for outdoor spaces. Similarly, a composite rail fence combines strength and longevity, making it ideal for residential and commercial use.

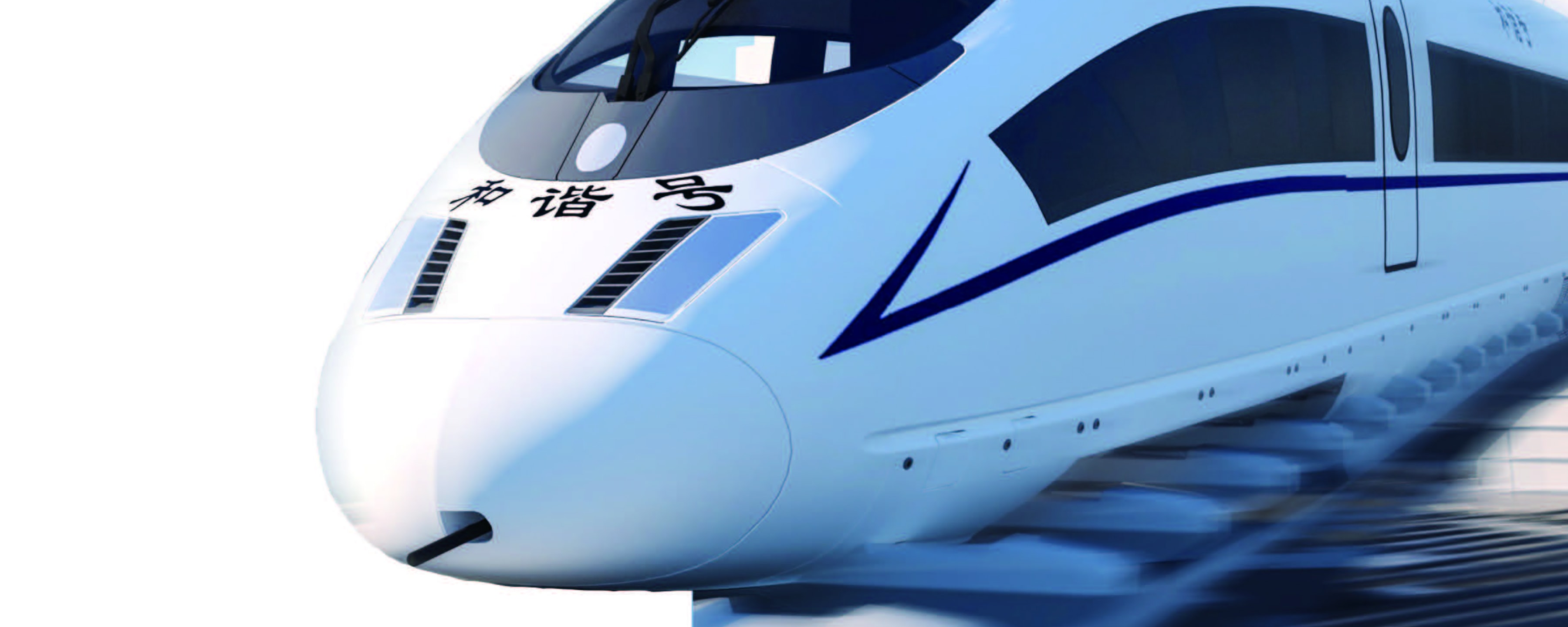

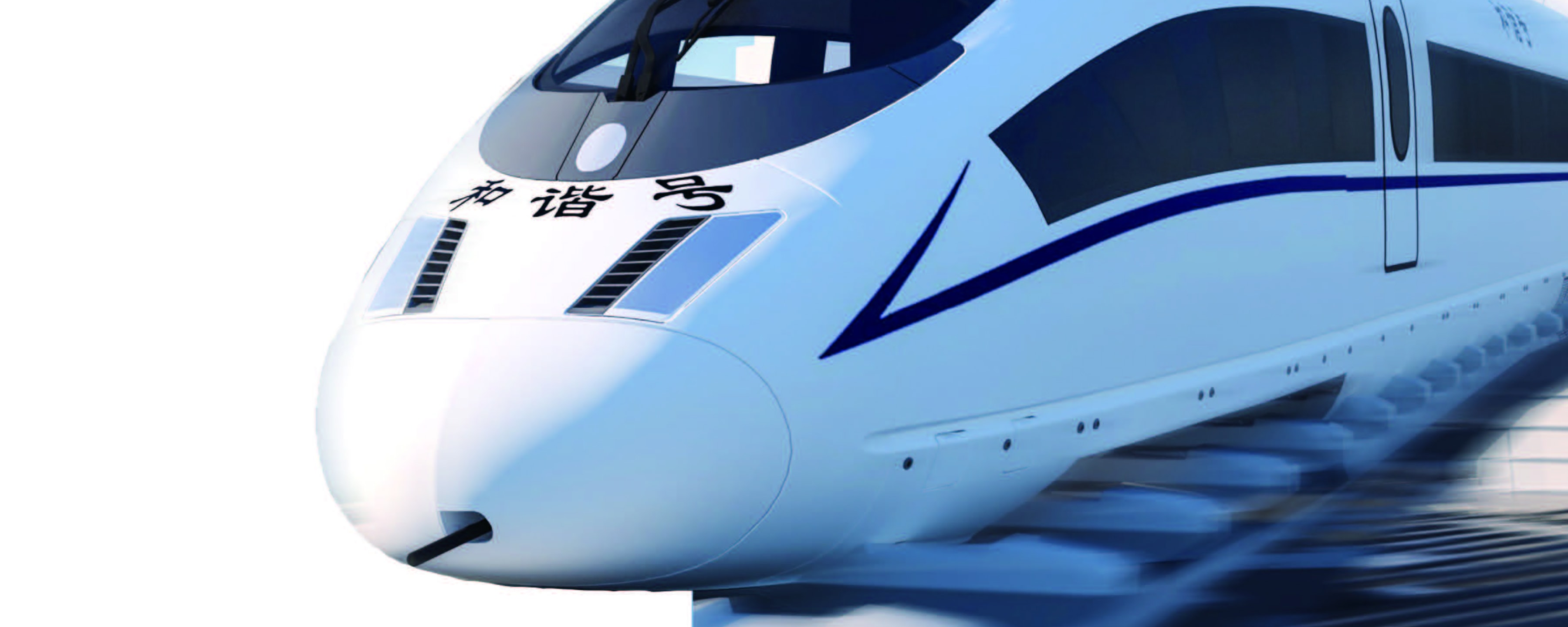

Rail & Transit

Rail & Transit

The application of fiber composite materials in rail transportation is increasingly widespread, particularly carbon fiber, glass fiber, and aramid composite materials. These materials offer several significant advantages over traditional metals:

The application of fiber composite materials in rail transportation is increasingly widespread, particularly carbon fiber, glass fiber, and aramid composite materials. These materials offer several significant advantages over traditional metals:

1. Lightweight High Strength: Composite materials have low density and high strength. For instance, the density of carbon fiber is only 57% that of aluminum, yet its strength is 3.6 times that of aluminum, significantly reducing the weight of vehicle structural components.

2. Good Flame Retardancy: Composite materials can enhance fire resistance by adjusting molecular structures or adding flame retardants, thereby improving train fire safety.

3. Excellent Fatigue Resistance: The fatigue strength of composite materials is comparable to their static strength, with crack propagation being minimal, enhancing the structural fatigue resistance.

4. High Damping: Composite materials effectively reduce vibrations, ensuring operational safety, reducing noise, and enhancing comfort.

5. Superior Corrosion Resistance: Composite materials exhibit strong resistance to corrosion in harsh environments, prolonging vehicle lifespan and reducing maintenance costs.

6. Excellent Design Flexibility: By selecting different matrices and fibers, along with adjusting molding processes, composite materials can meet diverse design requirements.

In the body structure of rail vehicles, the application of composite materials can reduce the overall vehicle mass by approximately 10%. For example, double-decker TGV trailers in France and articulated high-speed trains like the TTX in South Korea utilize composite material bodies, significantly reducing weight and enhancing passenger comfort.

1. Lightweight High Strength: Composite materials have low density and high strength. For instance, the density of carbon fiber is only 57% that of aluminum, yet its strength is 3.6 times that of aluminum, significantly reducing the weight of vehicle structural components.

2. Good Flame Retardancy: Composite materials can enhance fire resistance by adjusting molecular structures or adding flame retardants, thereby improving train fire safety.

3. Excellent Fatigue Resistance: The fatigue strength of composite materials is comparable to their static strength, with crack propagation being minimal, enhancing the structural fatigue resistance.

4. High Damping: Composite materials effectively reduce vibrations, ensuring operational safety, reducing noise, and enhancing comfort.

5. Superior Corrosion Resistance: Composite materials exhibit strong resistance to corrosion in harsh environments, prolonging vehicle lifespan and reducing maintenance costs.

6. Excellent Design Flexibility: By selecting different matrices and fibers, along with adjusting molding processes, composite materials can meet diverse design requirements.

In the body structure of rail vehicles, the application of composite materials can reduce the overall vehicle mass by approximately 10%. For example, double-decker TGV trailers in France and articulated high-speed trains like the TTX in South Korea utilize composite material bodies, significantly reducing weight and enhancing passenger comfort.

As a critical component of vehicles, the use of carbon fiber composite materials in bogies can reduce weight by 40%, as seen in Japan's "efWING" bogies. In braking systems, composite material brake discs cater to the lightweight and high-performance demands of high-speed trains.

Moreover, structures like luggage racks and equipment compartments also incorporate composite materials, such as the aramid honeycomb sandwich structure in China's CRH5 Harmony EMUs. This structure, light and high in strength, offers superior specific strength, making it ten times stronger than solid steel at an equivalent weight. These applications underscore the crucial role of composite materials in modern rail transportation, not only reducing vehicle weight but also enhancing overall vehicle performance and passenger comfort.

As a critical component of vehicles, the use of carbon fiber composite materials in bogies can reduce weight by 40%, as seen in Japan's "efWING" bogies. In braking systems, composite material brake discs cater to the lightweight and high-performance demands of high-speed trains.

Moreover, structures like luggage racks and equipment compartments also incorporate composite materials, such as the aramid honeycomb sandwich structure in China's CRH5 Harmony EMUs. This structure, light and high in strength, offers superior specific strength, making it ten times stronger than solid steel at an equivalent weight. These applications underscore the crucial role of composite materials in modern rail transportation, not only reducing vehicle weight but also enhancing overall vehicle performance and passenger comfort.

Get In Touch With Us!

To know more about our composite products and solutions, contact our experts! Here is how you can reach us.

Get In Touch With Us!

To know more about our composite products and solutions, contact our experts! Here is how you can reach us.

Popular Composite Materials

Popular Composite Materials

Related Composite Materials Industries

Related Composite Materials Industries

Composites Knowledge Hub

Composites Knowledge Hub