+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Top 5 Uses for Carbon Fiber Unidirectional Fabric in Modern Engineering

Carbon fiber unidirectional fabric is a cutting-edge material that has transformed the engineering world. Known for its exceptional strength, lightweight properties, and corrosion resistance, it has become a cornerstone for various high-performance applications. Engineers and designers across industries are leveraging this material to innovate and improve their products, from aerospace components to sports equipment.

What is Carbon Fiber Unidirectional Fabric?

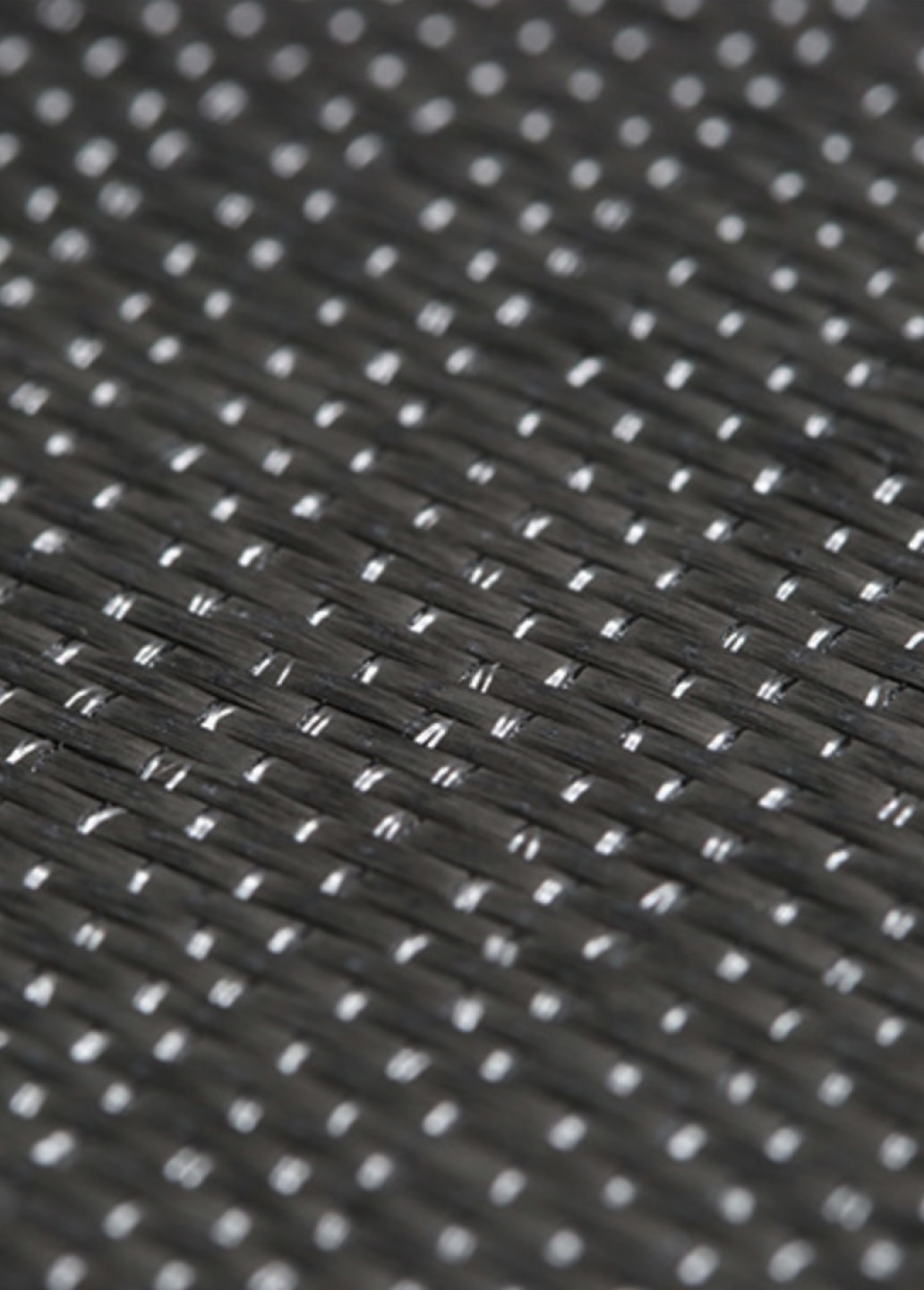

Carbon fiber unidirectional fabric refers to a type of composite material where all carbon fibers are aligned in a single direction. This specific alignment optimizes strength and stiffness along the designated axis, making it ideal for reinforcing structures in targeted directions. Unlike woven carbon fabrics, which interlace fibers in multiple directions, unidirectional carbon fabric eliminates crimping, ensuring better mechanical performance and load distribution.

Key features of carbon fiber unidirectional fabric include:

- Lightweight Composition: Offers reduced weight without sacrificing strength, which is critical for applications where performance and efficiency are priorities.

- Exceptional Tensile Strength: Its ability to resist stretching under tension makes it reliable for structural reinforcement.

- Corrosion and Chemical Resistance: Highly resistant to environmental factors, ensuring durability in harsh conditions.

- Versatility: Compatible with a variety of resin systems and manufacturing techniques for tailored applications.

Given these properties, unidirectional carbon fabric is now a vital material in modern engineering disciplines. Below, we discuss its top five uses in greater detail.

1. Aerospace Engineering

Carbon fiber composite material is widely used in aerospace engineering due to its exceptional strength-to-weight ratio. The aerospace industry was among the earliest adopters of carbon fiber unidirectional fabric, recognizing its unparalleled strength-to-weight ratio and durability. Aircraft and spacecraft operate under extreme conditions, including high speeds, intense pressure changes, and temperature extremes. These demanding environments require materials that are both lightweight and robust—qualities that unidirectional carbon fabric offers in abundance.

Applications in Aerospace:

- Wing and Fuselage Construction: Modern airplanes require lightweight wings and fuselage sections to enhance fuel efficiency and reduce emissions. Carbon fiber unidirectional fabric is used in these critical components to provide stiffness and strength while minimizing weight.

- Rotor and Propeller Blades: Helicopters, drones, and unmanned aerial vehicles (UAVs) rely on rotor and propeller blades made with unidirectional carbon fabric to maximize performance and efficiency. The material’s ability to dampen vibrations also ensures smoother operation.

- Spacecraft Components: In space exploration, where conditions are extreme, unidirectional carbon fabric is indispensable. It is used in constructing heat shields, satellite structures, and load-bearing components because of its ability to withstand high stress and temperature fluctuations.

By incorporating carbon fiber unidirectional fabric, aerospace engineers achieve higher safety standards, improved fuel economy, and longer-lasting aircraft components.

2. Automotive Engineering

The automotive industry is undergoing a transformation driven by the demand for sustainable, energy-efficient vehicles. Carbon fiber unidirectional fabric has emerged as a key material in this sector, providing a unique balance of strength, weight savings, and durability.

Applications in Automotive:

- Chassis Reinforcement: Lightweight chassis reinforced with unidirectional carbon fabric improves a vehicle's safety while reducing overall weight, leading to better fuel efficiency and enhanced handling.

- Body Panels: Car manufacturers are using carbon fiber body panels to reduce vehicle weight and improve aerodynamics. The material's sleek appearance is an added aesthetic bonus, especially for luxury and sports cars.

- Crash Protection: In collision-prone areas of vehicles, unidirectional carbon fabric is used to absorb impact energy effectively, ensuring passenger safety.

- Electric Vehicle (EV) Battery Cases: For electric vehicles, lightweight battery enclosures made from carbon fiber improve energy efficiency and vehicle range.

Brands like Tesla, Lamborghini, and McLaren heavily incorporate unidirectional carbon fabric into their designs, setting new benchmarks for performance and sustainability in the automotive industry.

3. Civil Engineering

In civil engineering, materials that can endure heavy loads, harsh environmental conditions, and time are paramount. Carbon fiber unidirectional fabric has become a game-changer in this field, particularly for retrofitting and strengthening aging infrastructure.

Applications in Civil Engineering:

- Bridge Reinforcement: Bridges are subjected to constant traffic loads and environmental stresses. Unidirectional carbon fabric is applied to reinforce beams, decks, and supports, extending the structure’s lifespan and ensuring safety.

- Seismic Retrofitting: Buildings in earthquake-prone regions are often retrofitted with carbon fiber materials to increase their resistance to seismic forces. The fabric’s lightweight nature ensures that it doesn’t add excessive weight to the structure.

- Pipeline Wrapping and Repair: For industrial pipelines transporting water, oil, or chemicals, carbon fiber unidirectional fabric provides an effective solution to prevent corrosion and leaks.

- Historical Building Preservation: Older buildings can be strengthened without altering their appearance using carbon fiber reinforcement systems.

The use of unidirectional carbon fabric in civil projects not only boosts structural integrity but also helps reduce long-term maintenance costs.

4. Sports Equipment Manufacturing

In the sports industry, the demand for high-performance equipment has led to widespread adoption of carbon fiber unidirectional fabric. Its ability to combine lightweight properties with high stiffness and strength has made it the material of choice for premium sports gear.

Applications in Sports:

- Cycling Frames: High-performance bicycles use carbon fiber frames to reduce weight and improve stiffness, making them ideal for competitive cycling.

- Tennis Rackets: Incorporating unidirectional carbon fabric enhances a racket's power, control, and shock absorption, providing players with a competitive edge.

- Golf Clubs: Lightweight yet durable shafts made from carbon fiber improve swing speed and accuracy for golfers.

- Fishing Rods: The fabric’s strength and flexibility allow fishing rods to handle heavy loads while remaining lightweight and responsive.

- Snowboards and Skis: Carbon fiber laminates enhance durability and performance in extreme conditions.

With unidirectional carbon fabric, manufacturers can create sports gear that is not only durable but also enhances athletes’ performance and experience.

5. Renewable Energy

As renewable energy technologies evolve, lightweight and durable materials like carbon fiber unidirectional fabric are essential for building efficient and reliable systems. The material’s high strength-to-weight ratio makes it particularly useful in wind, solar, and hydroelectric applications.

Applications in Renewable Energy:

- Wind Turbine Blades: Wind turbines require long blades to generate maximum power. Unidirectional carbon fabric is used in blade construction to minimize weight while providing the necessary strength and stiffness to handle high wind forces.

- Solar Panel Supports: Solar panel mounting systems exposed to harsh weather conditions benefit from carbon fiber’s resistance to corrosion and environmental degradation.

- Hydropower Components: In hydroelectric plants, unidirectional carbon fabric is used to build components like turbine blades, which must endure constant water pressure and wear.

By using unidirectional carbon fabric, renewable energy projects achieve higher efficiency, reduced maintenance costs, and increased system longevity.

Why Carbon Fiber Unidirectional Fabric is a Game-Changer

The growing use of carbon fiber unidirectional fabric in engineering stems from its unique advantages:

- Exceptional Strength-to-Weight Ratio: Provides unmatched structural reinforcement without adding unnecessary weight.

- Directional Stiffness: Maximizes mechanical performance along a specific axis, making it ideal for targeted reinforcement.

- Corrosion Resistance: Stands up to moisture, chemicals, and extreme temperatures, ensuring long-term durability.

- Versatility: Compatible with different resin systems and manufacturing techniques for customizable applications.

Its adoption across industries is not only improving product performance but also promoting sustainability by enabling energy savings and reducing material waste.

Conclusion

From aerospace to renewable energy, carbon fiber unidirectional fabric is redefining the possibilities of modern engineering. Its lightweight, high-strength properties have made it a cornerstone for innovation in diverse fields. Whether reinforcing bridges, improving vehicle performance, or enhancing sports gear, unidirectional carbon fabric has proven to be an indispensable material for today’s technological advancements.

Popular Composite Materials

Popular Composite Materials

Composites Knowledge Hub

Composites Knowledge Hub