+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Carbon Fiber Multiaxial Fabric

Hybrid Woven Fabric

+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

What are Basalt Fiber Products? The Future of Basalt Textile Innovation

What are Basalt Fiber Products?

Definition and Composition

Basalt fiber products are materials made from basalt rock, a natural volcanic stone. These fibers are created through a process of melting basalt at high temperatures and then extruding it into fine strands. The resulting fibers are lightweight, strong, and highly resistant to heat and chemicals.

Advantages of Basalt Fiber

Basalt fibers offer numerous advantages over traditional materials, such as glass and carbon fibers. They have excellent tensile strength, resistance to high temperatures, and low thermal conductivity. Additionally, basalt fiber products are environmentally friendly, as they utilize abundant natural resources and have a low carbon footprint in production.

The Role of Basalt Textile in Modern Applications

Definition of Basalt Textile

Basalt textile refers to fabrics and materials made from basalt fibers. These textiles can be woven, knitted, or non-woven, resulting in versatile products suitable for various applications, from construction to fashion.

Applications of Basalt Textile

Basalt textiles are gaining traction in several industries:

- Construction: Used in reinforcement for concrete, basalt textiles enhance the durability and strength of structures.

- Automotive: Lightweight basalt fiber composites are being integrated into car manufacturing for improved fuel efficiency.

- Aerospace: The aerospace industry benefits from basalt textiles for their heat resistance and lightweight properties, enhancing performance and safety.

Types of Basalt Fiber Products

Basalt fiber products encompass a range of innovative materials, each tailored for specific applications and benefits. Here are some key types of basalt fiber products:

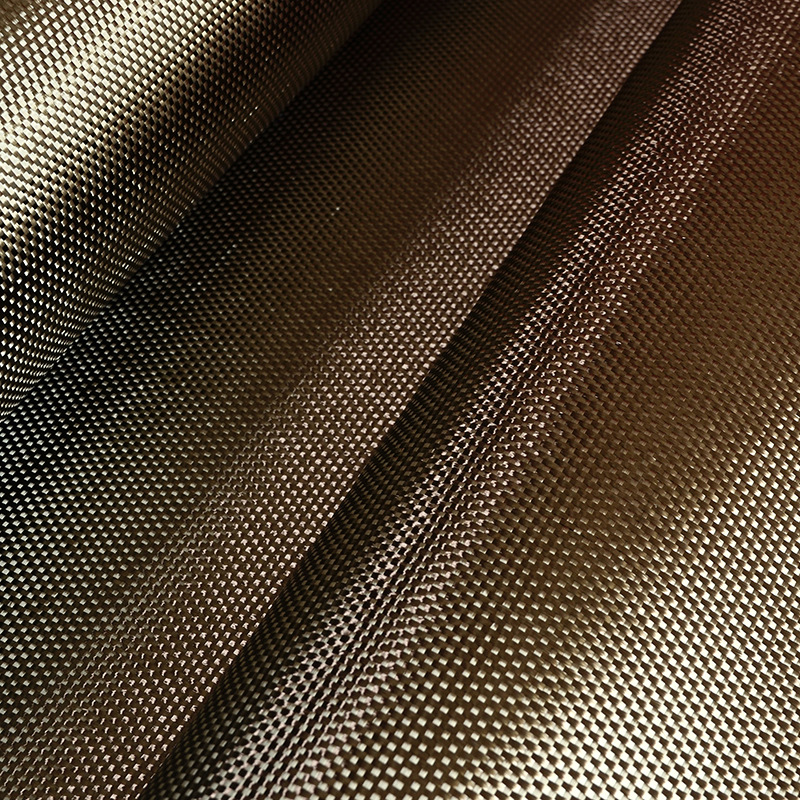

1. Basalt Fiber Woven Fabric

Basalt fiber woven fabric is created by interlacing basalt fibers in a specific pattern, resulting in a strong, lightweight material. This fabric is commonly used in applications such as automotive interiors, construction reinforcement, and thermal insulation due to its high tensile strength and thermal resistance.

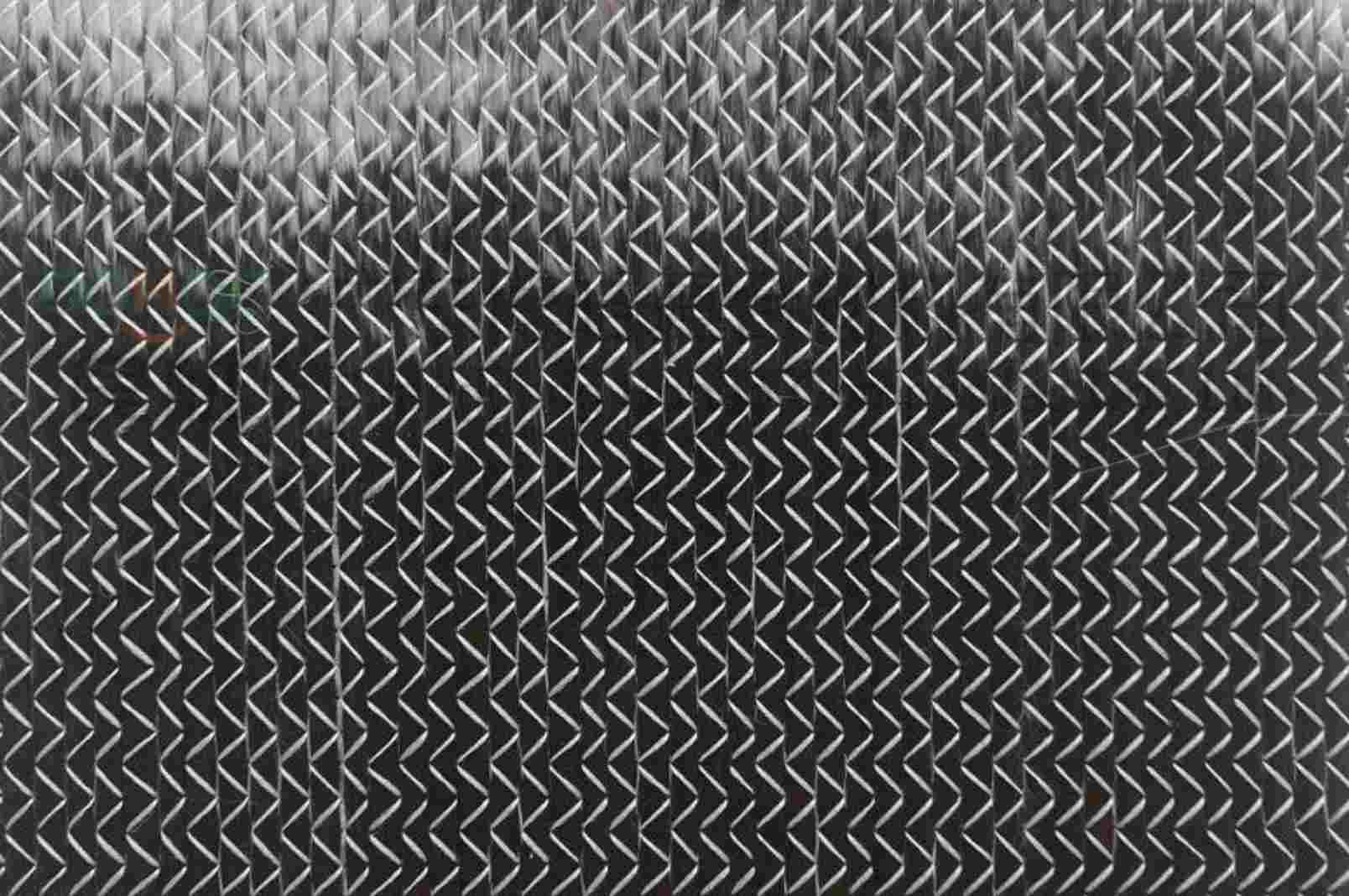

2. Basalt Fiber Warp Knitting Fabric

Warp knitting fabric made from basalt fibers offers unique flexibility and durability. This type of fabric is characterized by its intricate loop structure, making it suitable for applications requiring high strength and elasticity, such as composite materials in the aerospace and automotive industries.

3. Basalt Fiber Mat

Basalt fiber mats consist of randomly oriented basalt fibers bonded together, providing excellent insulation and reinforcement properties. These mats are commonly used in construction for thermal and sound insulation, as well as in the production of lightweight composite panels.

4. Basalt Fiber Grid

Basalt fiber grids are engineered to enhance the structural integrity of concrete and other materials. Used primarily in civil engineering and construction, these grids provide excellent tensile strength and crack resistance, making them ideal for road repair, bridge construction, and soil stabilization.

5. Basalt Fiber Sleeve

Basalt fiber sleeves are tubular structures made from basalt fibers, designed to provide protection and reinforcement for various components. They are often used in electrical and thermal insulation applications, as well as in the automotive and aerospace industries for safeguarding wires and hoses against heat and mechanical damage.

These diverse basalt fiber products highlight the material's versatility and effectiveness in addressing various industrial needs, from construction to aerospace.

Manufacturing Process of Basalt Fiber Products

Extraction and Melting

The process begins with the extraction of basalt rock, which is then crushed and heated to temperatures exceeding 1,400°C (2,552°F). This melting process transforms the rock into a viscous liquid.

Fiber Formation

Once molten, the basalt is extruded through spinnerets to form continuous fibers. These fibers can be cut to various lengths or used in their continuous form, depending on the desired application.

Fabric Production

Basalt fibers are then processed into textiles through weaving or knitting. This stage allows for the creation of various fabric types, from rigid composites to flexible textiles.

Benefits of Using Basalt Fiber Products

Durability and Strength

Basalt fiber products exhibit remarkable durability, making them ideal for high-stress applications. Their strength-to-weight ratio surpasses that of many traditional materials.

Thermal Resistance

With a high melting point, basalt fibers can withstand extreme temperatures without degrading, making them suitable for applications in harsh environments.

Environmental Benefits

Basalt is a sustainable resource, and basalt fiber production generates less pollution compared to synthetic fibers. This eco-friendly aspect makes basalt textiles a popular choice among environmentally conscious consumers.

Challenges and Considerations of Basalt Textile

Cost Factors

While basalt fiber products offer many benefits, the initial cost of production can be higher than traditional materials. However, the long-term savings in durability and maintenance often offset these initial expenses.

Market Awareness

The industry is still developing, and increased awareness of basalt fiber products and their benefits is needed to drive broader adoption in various sectors.

Conclusion

Summary of Key Points

Basalt fiber products and basalt textiles represent a promising innovation in materials science. Their unique properties, combined with environmental benefits, make them a valuable alternative to conventional fibers.

Encouragement to Explore Basalt Fiber

As industries seek sustainable and high-performance materials, the future of basalt fiber products looks bright. Exploring these innovative textiles can lead to exciting advancements across multiple fields.

FAQs of Basalt Textile

What are basalt fiber products used for?

Basalt fiber products are used in construction, automotive, aerospace, and various other industries for their strength, thermal resistance, and environmental benefits.

How does basalt textile differ from other textiles?

Basalt textile is made from natural basalt fibers, offering superior durability and thermal resistance compared to synthetic options like polyester or nylon.

Are basalt fiber products environmentally friendly?

Yes, basalt fibers are derived from natural resources and have a lower environmental impact compared to many synthetic fibers, making them a sustainable choice.

Can basalt textiles be recycled?

While basalt fibers are durable, recycling options are limited compared to traditional textiles. However, they can be used in composite applications after their initial use.

Where can I buy basalt fiber products?

Basalt fiber products can be found through specialized suppliers, manufacturers, and online retailers focusing on construction, automotive, and textile industries.

Popular Composite Materials

Popular Composite Materials

Composites Knowledge Hub

Composites Knowledge Hub

Tel:

86-13732282311

E-mail:

merlin@xcellentcomposites.com

Copyright © Hangzhou Xcellent Composites Limited. All Rights Reserved.