+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Carbon Fiber Multiaxial Fabric

Hybrid Woven Fabric

+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Non-woven

The application of non-woven fabrics in the realm of textile composite materials is relatively recent. Non-woven fabrics primarily consist of flat non-woven fabrics and orthogonal triaxial non-woven fabrics. By bonding multiple layers of flat non-woven fabrics through chemical adhesion or needle punching, three-dimensional non-woven fabrics are produced, with orthogonal triaxial non-wovens finding application in special composite material components for aerospace. Under load stress, non-woven fabrics distribute loads uniformly, possess good damage stability, and can be used as alternatives to steel in concrete structures.

Various nonwoven composite material products have been widely applied in aerospace, environmental filtration, healthcare, industry, agriculture, civil engineering, construction, sports equipment, home facilities, and many aspects of daily life.

Glass fiber nonwoven mats are extensively used in thermosetting and thermoplastic composites. Given the high volume of composite material components in the automotive industry, where one-third of the parts use sheet molding processes, the primary use of glass fiber nonwoven mat-reinforced composites is in automotive applications. These applications include exterior panels of car front ends, truck exterior panels, underbody panels, fenders, interior headliners, door panels, and interior frameworks (such as dashboards, door interiors, and seat frames).

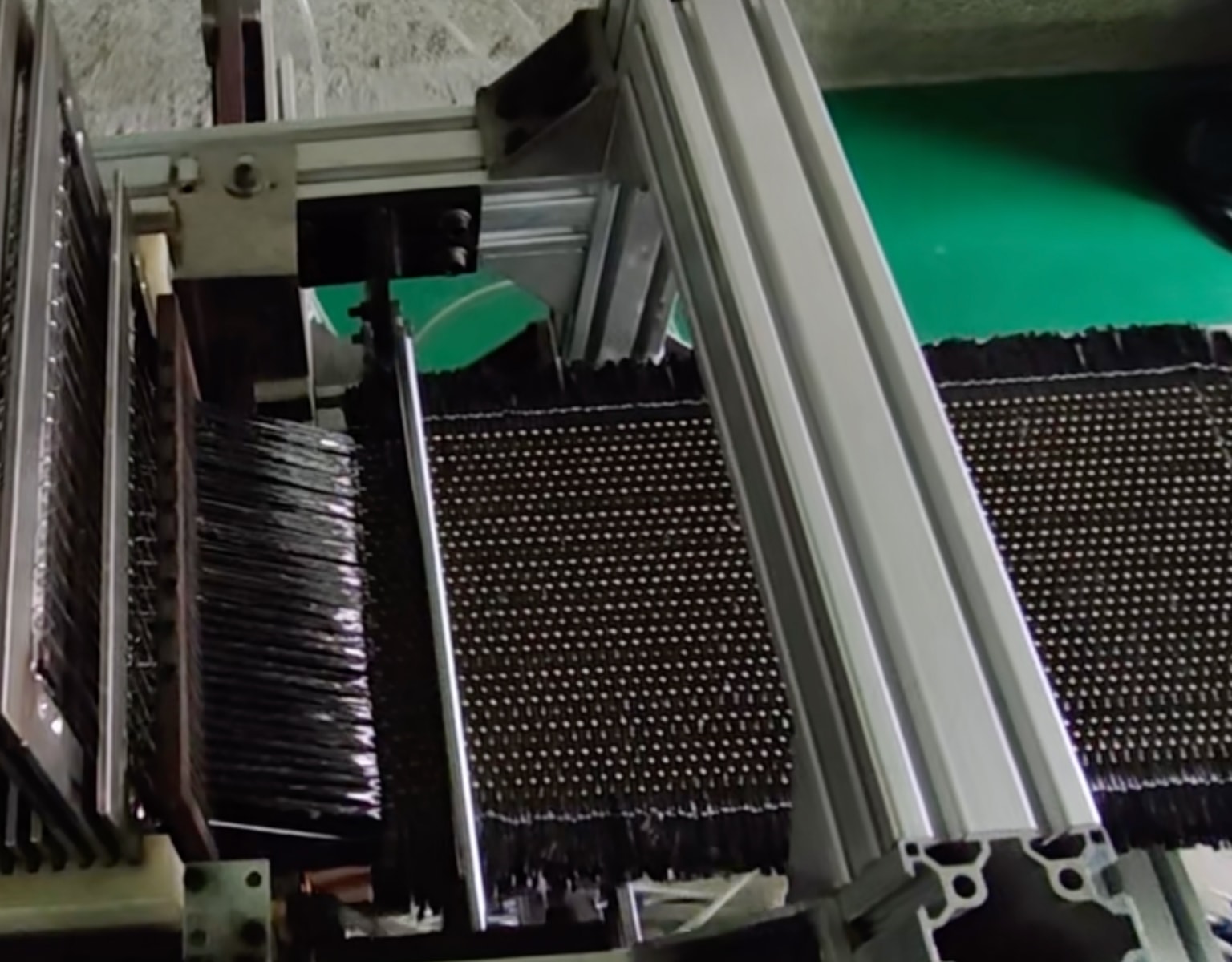

Carbon fiber needle-punched non-woven carbon/carbon composites possess several unmatched advantages, including light weight, good toughness, excellent ablation resistance, superior thermal shock resistance, high damage tolerance, high specific strength at high temperatures, and low thermal expansion coefficient. Due to these remarkable properties, they are widely used in rocket nozzles, missile nose cones, military supersonic aircraft, large civilian aircraft brake pads, and internal structural materials for high-temperature gas-cooled nuclear reactors. They are considered the best among all known high-temperature structural materials.

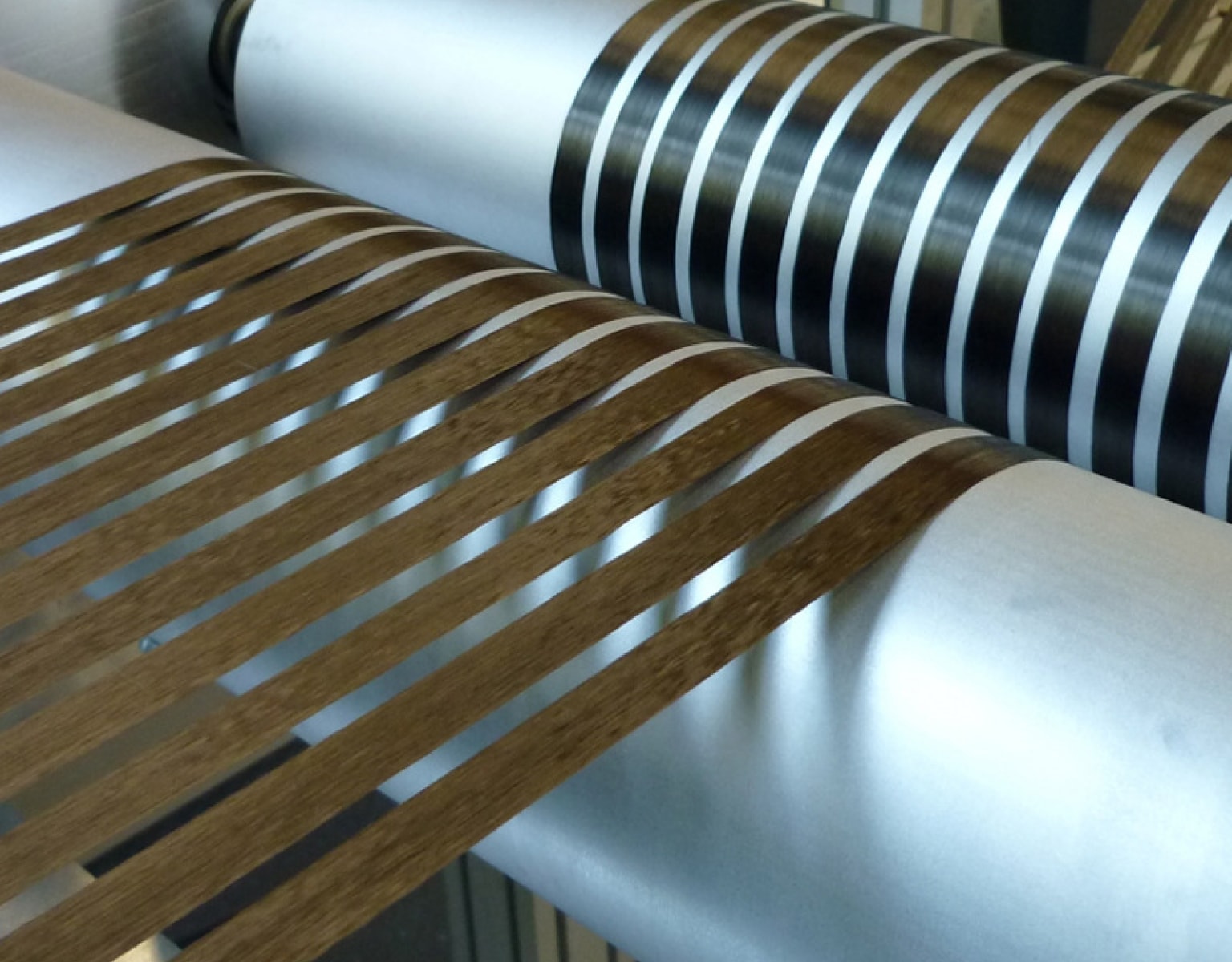

Stitched nonwoven structures have been used as reinforcement materials in the hulls of fiberglass boats, the fuselage of Boeing aircraft, and the large rear pressure bulkheads of Airbus A380s. In stitched nonwoven structures, the yarn layers are straight and parallel, unlike in woven fabrics where the yarns are crimped. Stitched yarns can be arranged in multiple axes and can be combined using glass roving, carbon fibers, and aramid fibers. Currently, the most complex stitched nonwoven structures can have up to 8 layers, plus an additional 1 to 2 layers of mat, with each layer stitched together by the yarn. For example, when weaving fiberglass grid fabric, the fiberglass yarns crimp at the intersections of the warp and weft, which can cause some filaments to break. However, in stitched nonwoven structures, the glass filaments do not crimp and break, allowing for maximum reinforcement efficiency.

Popular Composite Materials

Popular Composite Materials

Related Composite Materials Capabilities

Related Composite Materials Capabilities

Composites Knowledge Hub

Composites Knowledge Hub

Tel:

86-13732282311

E-mail:

merlin@xcellentcomposites.com

Copyright © Hangzhou Xcellent Composites Limited. All Rights Reserved.