+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Carbon Fiber Multiaxial Fabric

Hybrid Woven Fabric

+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

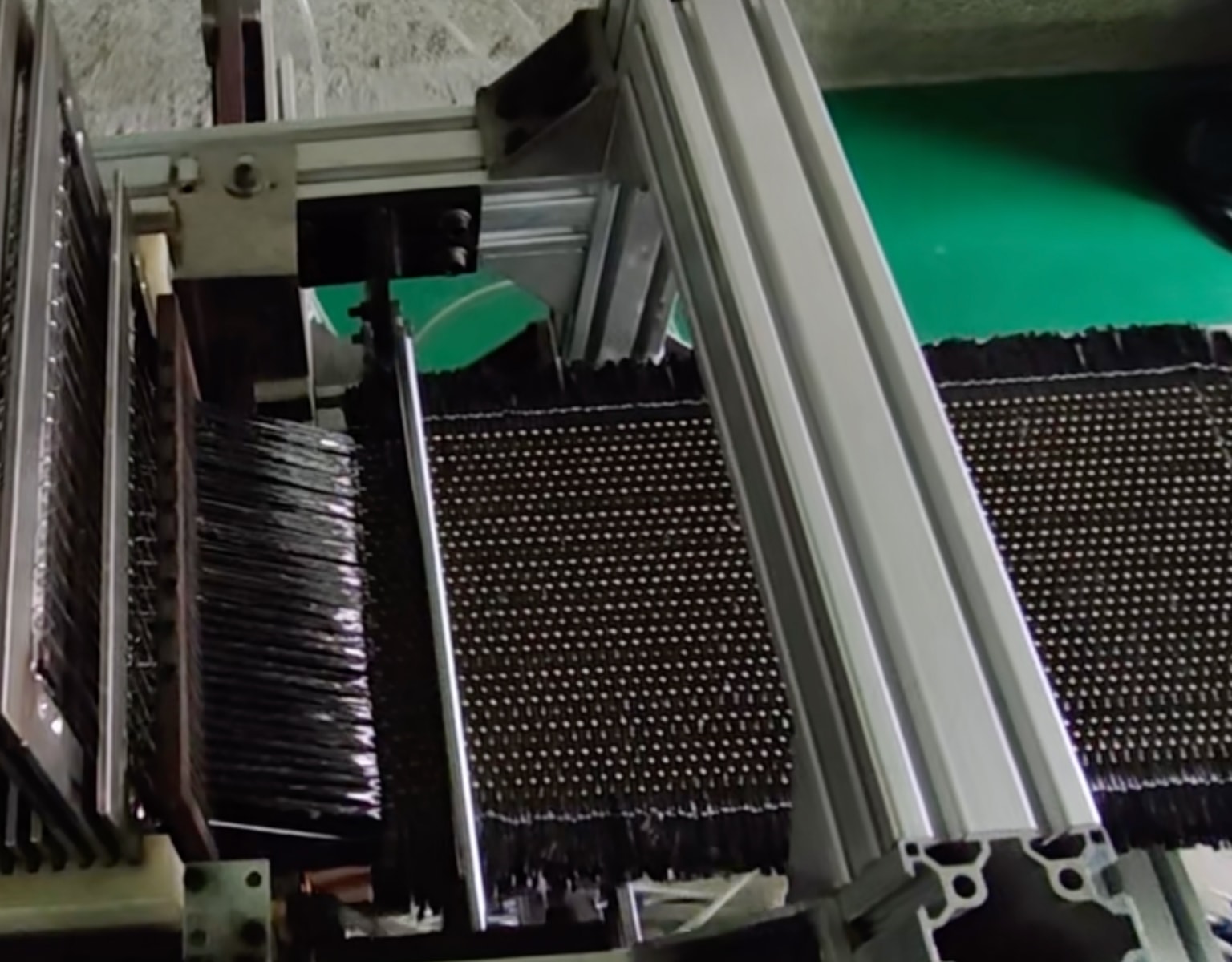

Knitting

Planar knitted fabrics exhibit superior impact resistance, energy absorption capabilities, and elasticity. They are divided into two structures: warp knitting and weft knitting on a plane. These fabrics possess significant stretchability, making them suitable for creating molded composite materials, yet they are not appropriate for load-bearing structures. The stability of knitted structures can be enhanced by incorporating reinforcement yarns or fibers that do not participate in the knitting process.

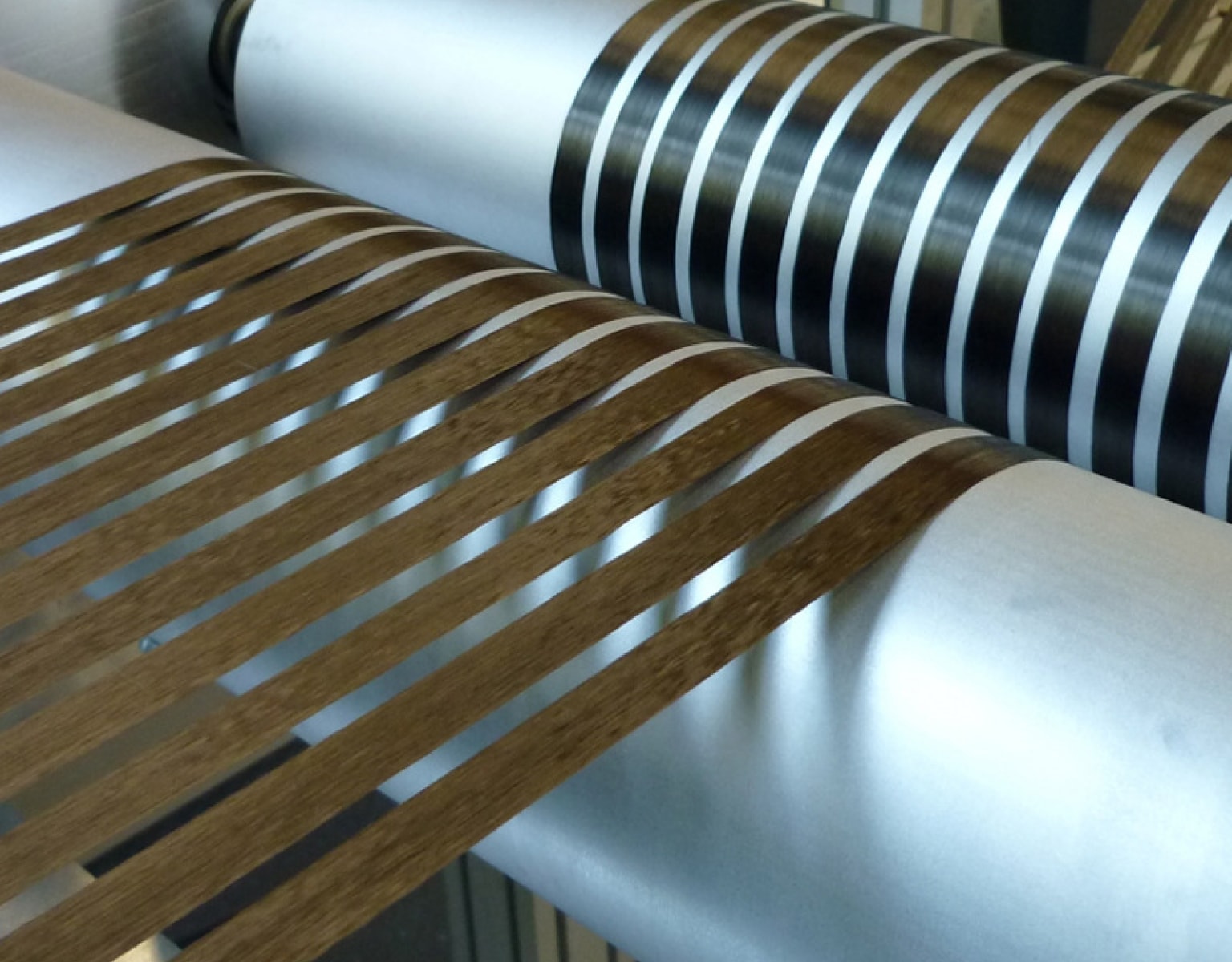

The main types of warp-knitted composite fabrics are unidirectional warp-knitted fabrics, biaxial warp-knitted fabrics, and multiaxial warp-knitted fabrics. Compared to traditional woven fabrics, warp-knitted axial fabrics have no yarn bending, with fibers arranged completely parallel and straight. Each layer has a high degree of orientation, allowing the tensile strength and modulus of the yarns to be fully utilized. Additionally, multiaxial warp-knitted fabrics have higher density and lower void content in their structure, enabling the production of composite materials with high fiber volume content.

Warp-knitted fabrics exhibit excellent drapability and preformability, making them suitable for processing into various complex shapes. In liquid molding processes such as resin transfer molding (RTM), they can serve as high fiber volume fraction preforms. This process is essentially a preforming process and does not require the use of a shaping agent.

Fiber channels easily form within warp-knitted fabrics, reducing infiltration pressure during resin penetration and promoting uniform resin distribution. When combined with resin, this prevents the formation of resin-rich interlayer pockets.

Due to the excellent mechanical properties, low manufacturing costs, and ease of processing, warp-knitted fabrics are now widely used in various high-performance composite materials. These applications span across fields such as aviation, aerospace, shipbuilding, automotive industry, sports equipment, construction, energy, and healthcare.

Popular Composite Materials

Popular Composite Materials

Related Composite Materials Capabilities

Related Composite Materials Capabilities

Composites Knowledge Hub

Composites Knowledge Hub

Tel:

86-13732282311

E-mail:

merlin@xcellentcomposites.com

Copyright © Hangzhou Xcellent Composites Limited. All Rights Reserved.