+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Features of Quartz Fiber Fabric for Different Applications

Quartz fiber fabric is a remarkable material that has gained prominence in various industries due to its unique properties and versatility. Made from high-purity quartz fibers, this fabric is designed to endure extreme conditions while maintaining its structural integrity. It is often used in critical applications that require a combination of heat resistance, chemical stability, and lightweight performance. In this comprehensive blog, we will explore the key features of quartz fiber fabric and quartz fiber cloth, delving into their applications, benefits, and why they are the material of choice for many demanding industries.

What Is Quartz Fiber Fabric?

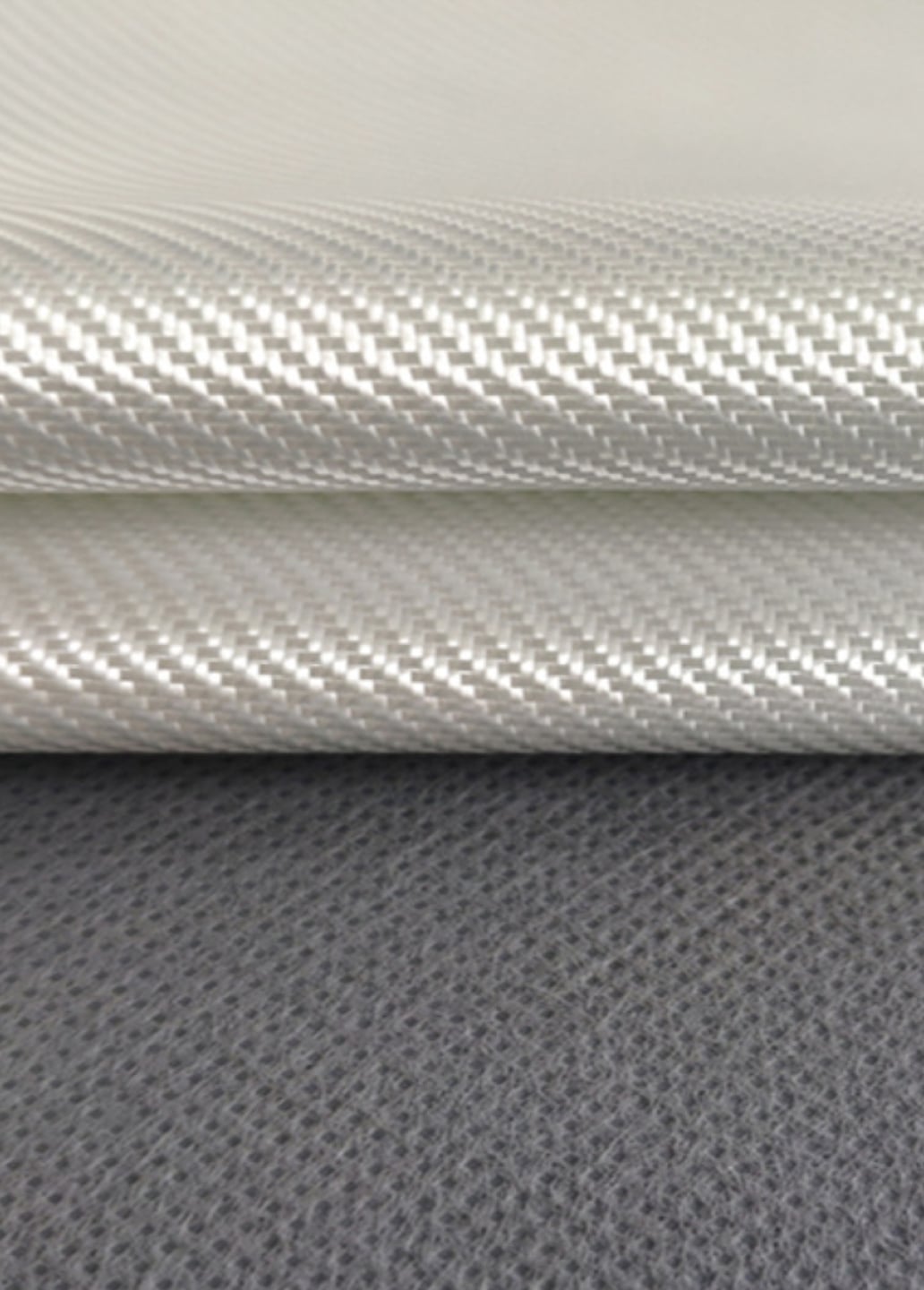

Quartz fiber fabric is manufactured from continuous filaments of fused quartz. These filaments are carefully woven into fabrics or cloths, creating a material with exceptional strength, heat resistance, and stability. The term quartz fiber cloth is often used interchangeably with quartz fiber fabric, though it may specifically refer to woven materials designed for specific applications.

Quartz fibers are distinct from other types of fibers due to their ability to withstand high temperatures and resist chemical degradation. This makes them an essential material in industries such as aerospace, electronics, energy, and manufacturing, where performance under extreme conditions is critical.

Quartz crystals are used to create a specialized product known as quartz fiber fabric. These fabrics, often referred to as quartz or silica fiber fabrics, typically contain a silicon dioxide (SiO₂) content of 70% or higher. In some cases, the SiO₂content in quartz fabric can reach up to 96%, depending on the manufacturer. Customers can select products based on their specific requirements from the available market options.

Quartz cloth, also known as silica cloth, is highly resistant to high temperatures, making it ideal for various applications. One common use is in fire blankets, which are designed to protect individuals during fire emergencies. Other applications include welding pads, welding curtains, and blankets used in welding processes.

Thanks to its excellent heat resistance, quartz fiber fabric is widely used for protective purposes. It can withstand temperatures as high as 1000°C for extended periods. However, exposure to temperatures around 1400°C for prolonged durations can damage the fabric’s components, particularly when used in fire blankets.

Quartz fiber cloth is crafted by weaving quartz or silica threads into a cohesive structure. The weave patterns—such as plain, twill, or satin—are pre-determined and tailored to meet market demands. This weaving process ensures the fabric's durability and adaptability for diverse applications.

Features of Quartz Fiber Fabric and Quartz Fiber Cloth

1. Thermal Resistance

Quartz fiber fabric is renowned for its ability to withstand extremely high temperatures. It can operate continuously at temperatures up to 1050°C (1922°F) without experiencing significant degradation. This feature makes it an ideal choice for applications exposed to intense heat, such as:

- Aerospace Applications: Quartz fiber fabric is commonly used as thermal insulation in rocket nozzles, heat shields, and spacecraft components. These applications require materials that can endure the extreme temperatures generated during launch and re-entry.

- Industrial Settings: In industries involving high-temperature processes, such as metalworking and glass manufacturing, quartz fiber fabric serves as a protective barrier, insulation layer, or cover for equipment exposed to heat.

2. High Tensile Strength

Despite its lightweight nature, quartz fiber fabric boasts impressive tensile strength, allowing it to endure mechanical stress and maintain its structural integrity. This property is particularly advantageous in:

- Composite Materials: Quartz fiber fabric is often used as a reinforcing material in composite structures. These composites are lightweight yet strong, making them suitable for applications in aerospace, automotive, and construction industries.

- Structural Components: Its strength makes it ideal for reinforcing critical components that experience heavy loads or high impact forces.

3. Chemical Inertness

Quartz fiber fabric exhibits excellent resistance to chemical attacks from most acids, alkalis, and solvents. This chemical inertness ensures long-lasting performance in environments where other materials may corrode or degrade. Key applications include:

- Chemical Processing Plants: Quartz fiber fabric is used as liners for tanks, reactors, and pipes to protect against corrosive chemicals.

- Corrosion Resistance Applications: It serves as a protective barrier in environments exposed to harsh chemicals, ensuring durability and safety.

4. Low Dielectric Constant

Quartz fiber cloth is a preferred material in the electronics and telecommunications industries due to its low dielectric constant and low loss factor. These properties enable efficient signal transmission and insulation, making it suitable for:

- Printed Circuit Boards (PCBs): Quartz fiber fabric serves as a substrate material for high-frequency PCBs, ensuring minimal signal interference and loss.

- Microwave and RF Applications: It is used in waveguides, antenna components, and other devices that require precise signal performance.

5. Lightweight Design

Quartz fiber fabric combines strength and performance with a lightweight structure, which is essential for applications where weight reduction is critical. Examples include:

- Aerospace Components: Lightweight materials like quartz fiber fabric contribute to fuel efficiency and improved performance in aircraft and spacecraft.

- Sports Equipment: High-performance sports gear, such as helmets and racing equipment, often incorporates quartz fiber fabric for its lightweight and durable properties.

6. Dimensional Stability

Quartz fiber cloth retains its shape and properties under extreme conditions, including high temperatures, mechanical stress, and chemical exposure. This stability ensures consistent performance in:

- Thermal Insulation Blankets: These are used in environments requiring precision and reliability, such as space exploration and industrial manufacturing.

- Protective Covers: Quartz fiber fabric is often used as protective layers for machinery and equipment that experience temperature fluctuations.

7. UV and Radiation Resistance

Quartz fiber fabric is resistant to UV radiation and certain types of ionizing radiation, ensuring long-term stability and performance. Applications benefiting from this feature include:

- Outdoor Protective Layers: Quartz fiber cloth is used to shield outdoor equipment from UV damage and weathering.

- Nuclear Industry: It serves as a protective material for shielding and insulating components exposed to radiation in nuclear power plants.

Applications of Quartz Fiber Fabric

Quartz fiber reinforcements are widely used in advanced composite materials, providing exceptional strength and thermal stability for applications in aerospace, automotive, and industrial sectors.

Aerospace and Defense

The aerospace and defense sectors require materials that can withstand extreme conditions while maintaining lightweight and durable characteristics. Quartz fiber fabric plays a pivotal role in these industries through applications such as:

- Thermal Insulation: Used in rocket nozzles, heat shields, and spacecraft thermal protection systems.

- Reinforced Panels: Composite panels reinforced with quartz fiber fabric are used in aircraft structures to provide strength and reduce weight.

Electronics and Telecommunications

Quartz fiber cloth is a vital component in the electronics and telecommunications sectors due to its dielectric properties and heat resistance. It is used in:

- Circuit Boards: As a substrate material for high-frequency PCBs, ensuring efficient signal transmission.

- Microwave Technology: Quartz fiber cloth is used in waveguides, antennas, and other high-frequency applications.

Industrial Manufacturing

Quartz fiber fabric’s heat resistance and chemical inertness make it indispensable in industrial settings. Applications include:

- Insulation Wraps: For furnaces, boilers, and other high-temperature equipment.

- Protective Linings: Used in chemical processing equipment to prevent corrosion and degradation.

Energy Sector

The energy sector benefits from quartz fiber fabric’s unique properties in applications such as:

- Nuclear Power Plants: Quartz fiber fabric serves as insulation and radiation shielding in reactors.

- Solar Panels: It is used as a protective layer for solar panel components, ensuring durability in outdoor conditions.

Medical and Scientific Applications

In medical and scientific fields, quartz fiber cloth is valued for its purity, inertness, and resistance to extreme conditions. Examples include:

- Laboratory Equipment: Insulation for high-temperature scientific instruments.

- Cleanroom Applications: Protective layers in environments requiring strict contamination control.

Conclusion

Quartz fiber fabric and quartz fiber cloth are unparalleled materials in terms of their ability to withstand extreme conditions while maintaining strength, stability, and performance. Their unique features, including thermal resistance, chemical inertness, and lightweight design, make them indispensable across industries ranging from aerospace and electronics to industrial manufacturing and energy. Whether you're designing high-performance components or seeking reliable insulation materials, quartz fiber fabric offers a solution that combines innovation with durability.

Read More: An Introduction to 3D Mesh Fabric and 3D Knitted Fabric

Popular Composite Materials

Popular Composite Materials

Composites Knowledge Hub

Composites Knowledge Hub