+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

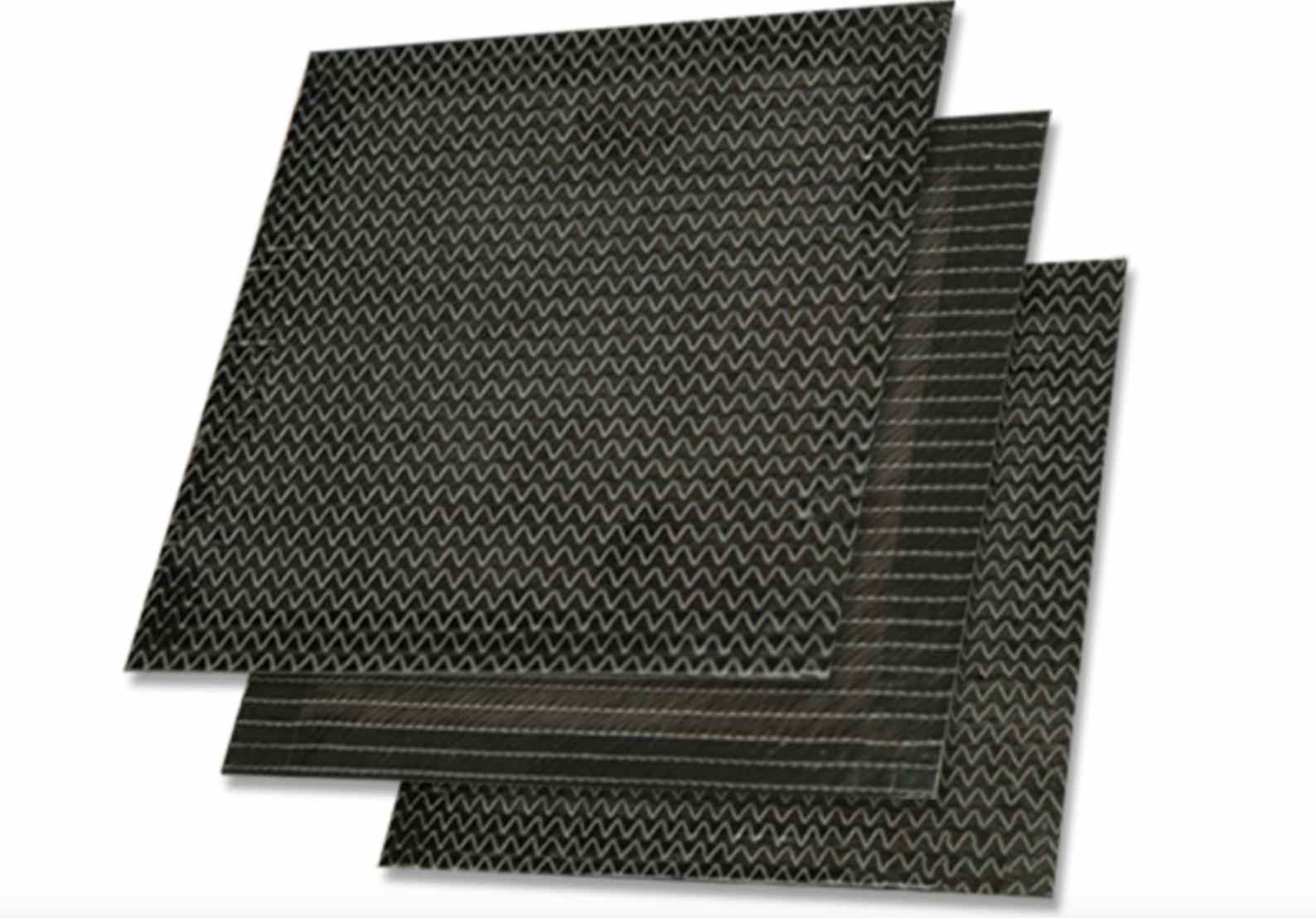

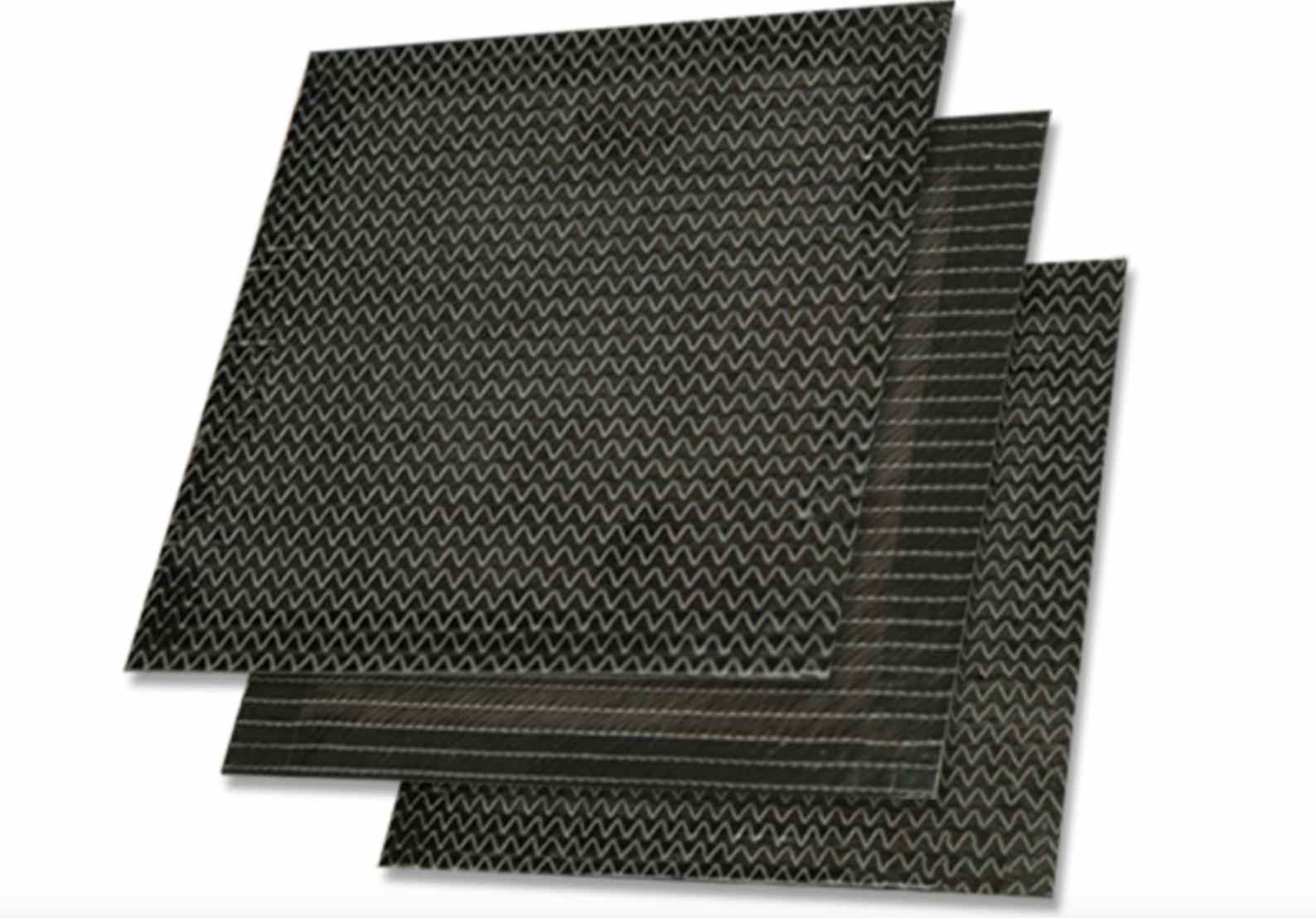

Carbon Fiber Multiaxial Fabric

Features of Multiaxial Carbon Fiber Fabric

| 01. | Non-crimped fibers: | Fibers in multiaxial fabrics are in a non-crimped state, allowing them to fully utilize their original mechanical properties, thereby enhancing the overall strength and durability of the material. |

| 02. | Multilayer and multidirectional structure: | Composed of multiple layers of straight and parallel yarns bound together through warp-knitting, this structure enables the material to exhibit excellent mechanical performance in multiple directions. |

| 03. | Superior mechanical properties: | Multiaxial fabrics demonstrate outstanding tensile, compressive, and impact resistance due to their structural characteristics, making them highly useful in applications requiring high-performance materials. |

| 04. | Design flexibility: | They can be designed to exhibit in-plane isotropic or anisotropic tensile properties by adjusting the strength and orientation of the binder yarns as needed. |

| 05. | Good shear performance: | The introduction of two sets of diagonal yarns suppresses shear deformation in the fabric, resulting in good shear performance. |

| 06. | Low manufacturing cost: | High K carbon fibers can be used to achieve the weaving effect of low K carbon fibers, reducing manufacturing costs. |

| 07. | Good resin impregnation: | Due to its structural characteristics, resin can better impregnate the entire fabric, enhancing the reinforcing properties of the composite material. |

Biaxial Carbon Fiber & Triaxial Carbon Fiber

Multiaxial carbon fiber fabrics refer to composite materials that consist of carbon fibers arranged in multiple orientations. This design allows for improved mechanical properties, such as enhanced strength and stiffness, across different loading directions.

Two Types:

-

Biaxial Carbon Fiber Fabric: This type typically has carbon fibers oriented in two perpendicular directions (e.g., 0° and 90°), which provides strength and stiffness in both the longitudinal and transverse directions.

-

Triaxial Carbon Fiber Fabric: This type features fibers oriented at three angles (e.g., 0°, 90°, and ±45°), offering superior torsional strength and multidirectional performance.

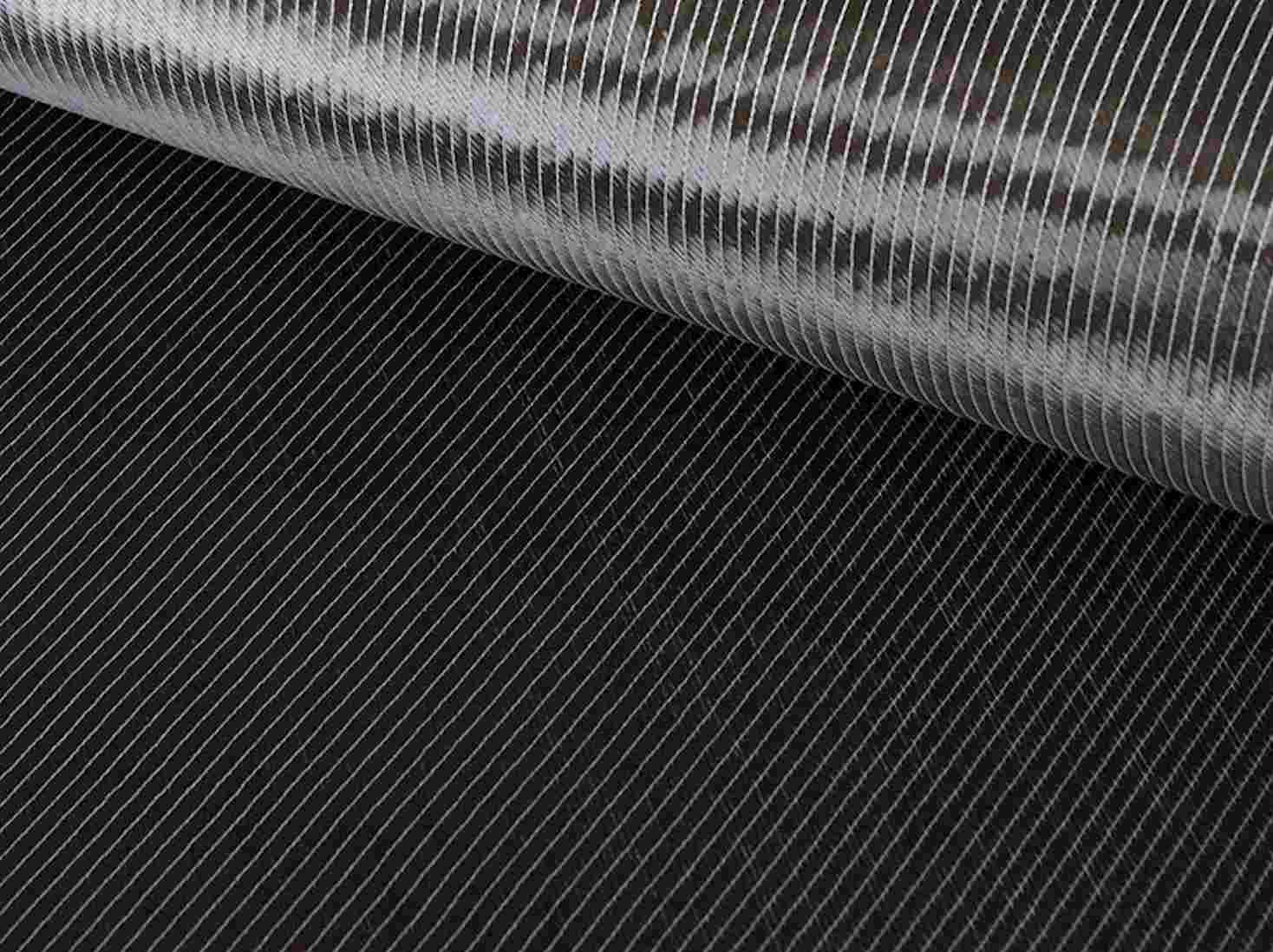

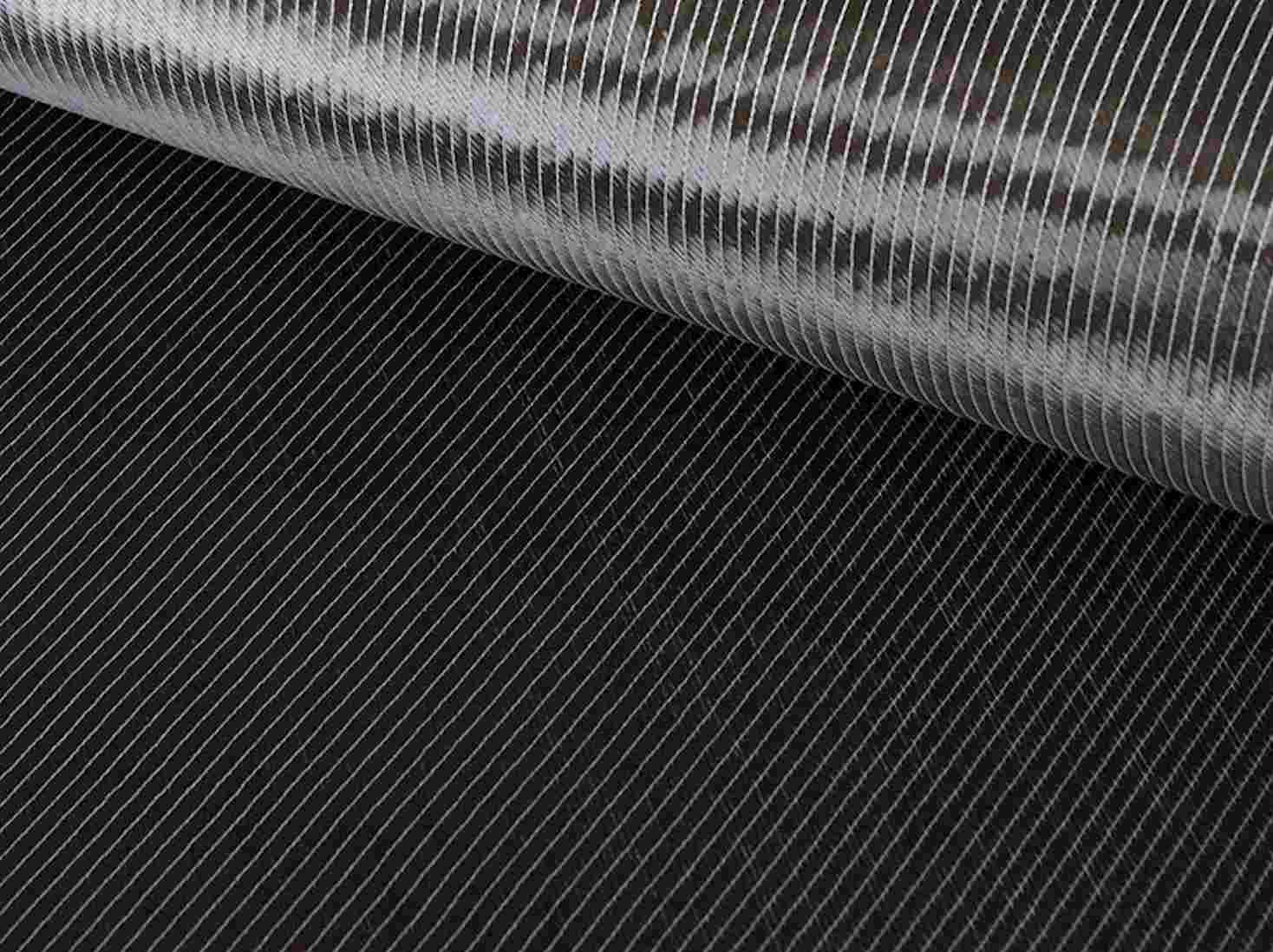

Biaxial Carbon Fiber: A bried look

Biaxial carbon fiber is a composite material that consists of carbon fibers arranged in two perpendicular directions. This configuration allows for enhanced strength and stiffness in both the longitudinal and transverse directions. Typically, biaxial carbon fiber is produced by weaving carbon fibers into a fabric, which is then infused with a resin to create a solid composite material.

Triaxial Carbon Fiber: A bried look

Triaxial carbon fiber features a three-dimensional arrangement of carbon fibers, typically oriented at angles of 0°, 90°, and ±45°. This structure provides enhanced strength and stiffness compared to biaxial fabrics, making it particularly effective at resisting torsional loads and improving overall structural integrity.

Get Price of Composite Materials

Get Price of Composite Materials

E-mail:

Address:

NO.61, XIANGYANGJIAYUAN, XIAOSHAN, HANGZHOU, CHINA

Related Composite Materials

Related Composite Materials

Carbon Fiber Spread Tow Fabric

Spread tow fabric is a fabric woven using spread yarn and is a new type of carbon fiber reinforced material. This fabric has characteristics such as low yarn bending, low surface density, good lay-flat properties, and high design flexibility.

1414 Aramid Fiber Woven Fabrics

Xcellent Composites produces aramid fabrics primarily using para-aramid 1414, and can design them into various fabric structures such as plain, twill, or satin weave, as well as more complex weaving patterns to adjust their mechanical properties and aesthetic characteristics.

Fiberglass Woven Fabric

Xcellent Composites produces a series of fiberglass woven fabrics designed for various applications, including fabrics for electronic printed circuit boards, expansion fabrics, and filter fabrics.

Basalt Fiber Woven Fabric

Basalt mesh fabric is made by twisting basalt fibers and then applying a resin coating. The mesh structure enhances the fabric's stability and durability, making it suitable for reinforcing concrete and road repairs.

Carbon Fiber Spread Tow Fabric

Spread tow fabric is a fabric woven using spread yarn and is a new type of carbon fiber reinforced material. This fabric has characteristics such as low yarn bending, low surface density, good lay-flat properties, and high design flexibility.

1414 Aramid Fiber Woven Fabrics

Xcellent Composites produces aramid fabrics primarily using para-aramid 1414, and can design them into various fabric structures such as plain, twill, or satin weave, as well as more complex weaving patterns to adjust their mechanical properties and aesthetic characteristics.

Fiberglass Woven Fabric

Xcellent Composites produces a series of fiberglass woven fabrics designed for various applications, including fabrics for electronic printed circuit boards, expansion fabrics, and filter fabrics.

Basalt Fiber Woven Fabric

Basalt mesh fabric is made by twisting basalt fibers and then applying a resin coating. The mesh structure enhances the fabric's stability and durability, making it suitable for reinforcing concrete and road repairs.

Composites Knowledge Hub

Composites Knowledge Hub