+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Composite material for industrial filtration

Composite material for industrial filtration

Quartz fiber filters offer high-temperature resistance and are commonly used in industrial applications for filtering air and gases. Fiberglass filters provide excellent dust and particulate filtration, often used in HVAC systems and industrial environments. Carbon fiber air filters deliver superior filtration efficiency and odor removal, making them ideal for air purification systems.

Composite material for industrial filtration

Quartz fiber filters offer high-temperature resistance and are commonly used in industrial applications for filtering air and gases. Fiberglass filters provide excellent dust and particulate filtration, often used in HVAC systems and industrial environments. Carbon fiber air filters deliver superior filtration efficiency and odor removal, making them ideal for air purification systems.

Industrial Filtration

Industrial Filtration

Fibrous filtration materials play a significant role in the filtration domain due to their simple structure, uniform porosity, exceptional filtration performance, high throughput, and cost-effectiveness. By combining different types of fibers, a synergistic blend of strengths and efficiency can be achieved, resulting in robust and highly effective filtration materials. Various manufacturing processes, such as different weave patterns in textiles, the knitting methods in knits, and the reinforcement techniques in nonwovens, can produce filtration materials adaptable to a variety of environments.

Fibrous filtration materials play a significant role in the filtration domain due to their simple structure, uniform porosity, exceptional filtration performance, high throughput, and cost-effectiveness. By combining different types of fibers, a synergistic blend of strengths and efficiency can be achieved, resulting in robust and highly effective filtration materials. Various manufacturing processes, such as different weave patterns in textiles, the knitting methods in knits, and the reinforcement techniques in nonwovens, can produce filtration materials adaptable to a variety of environments.

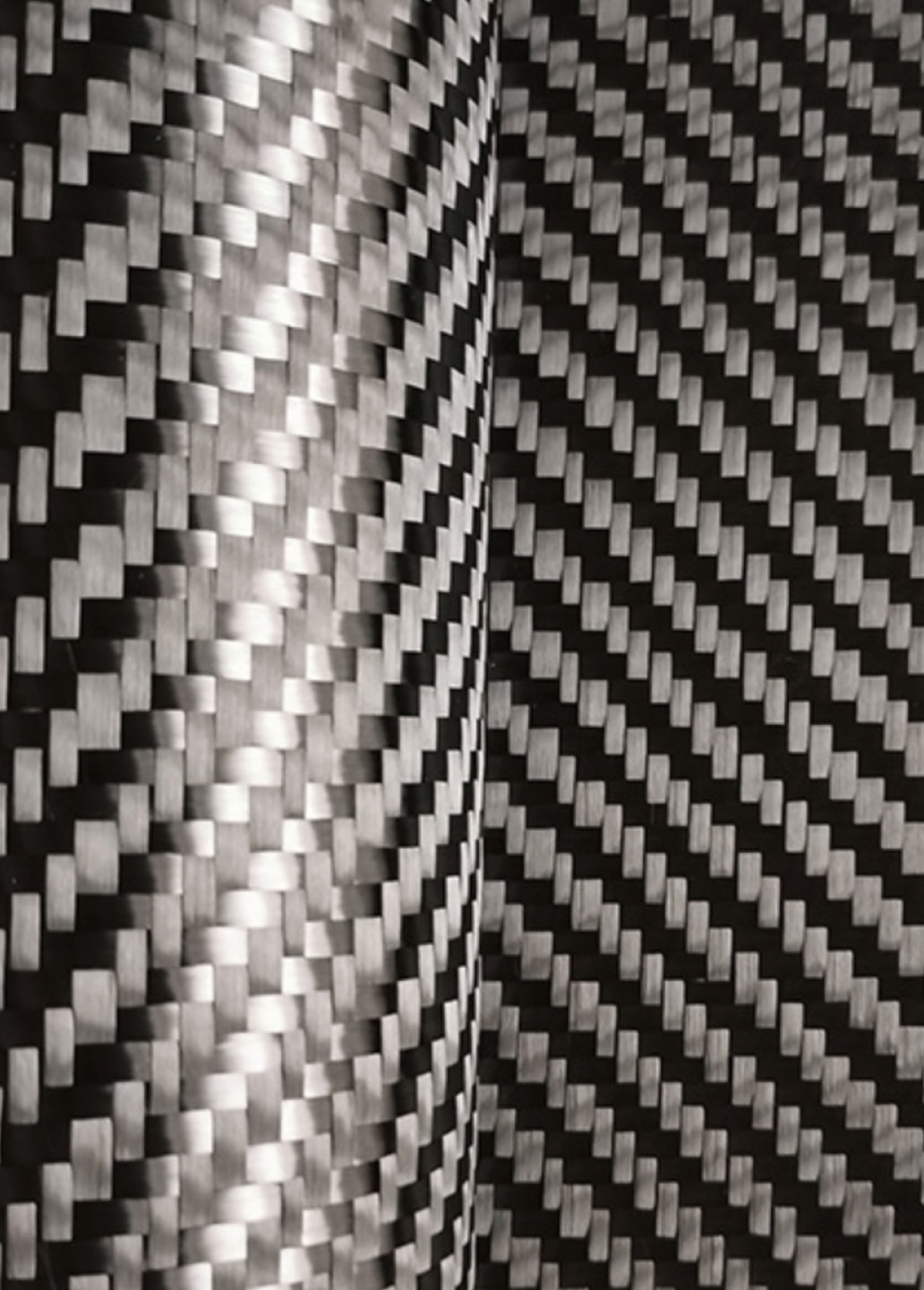

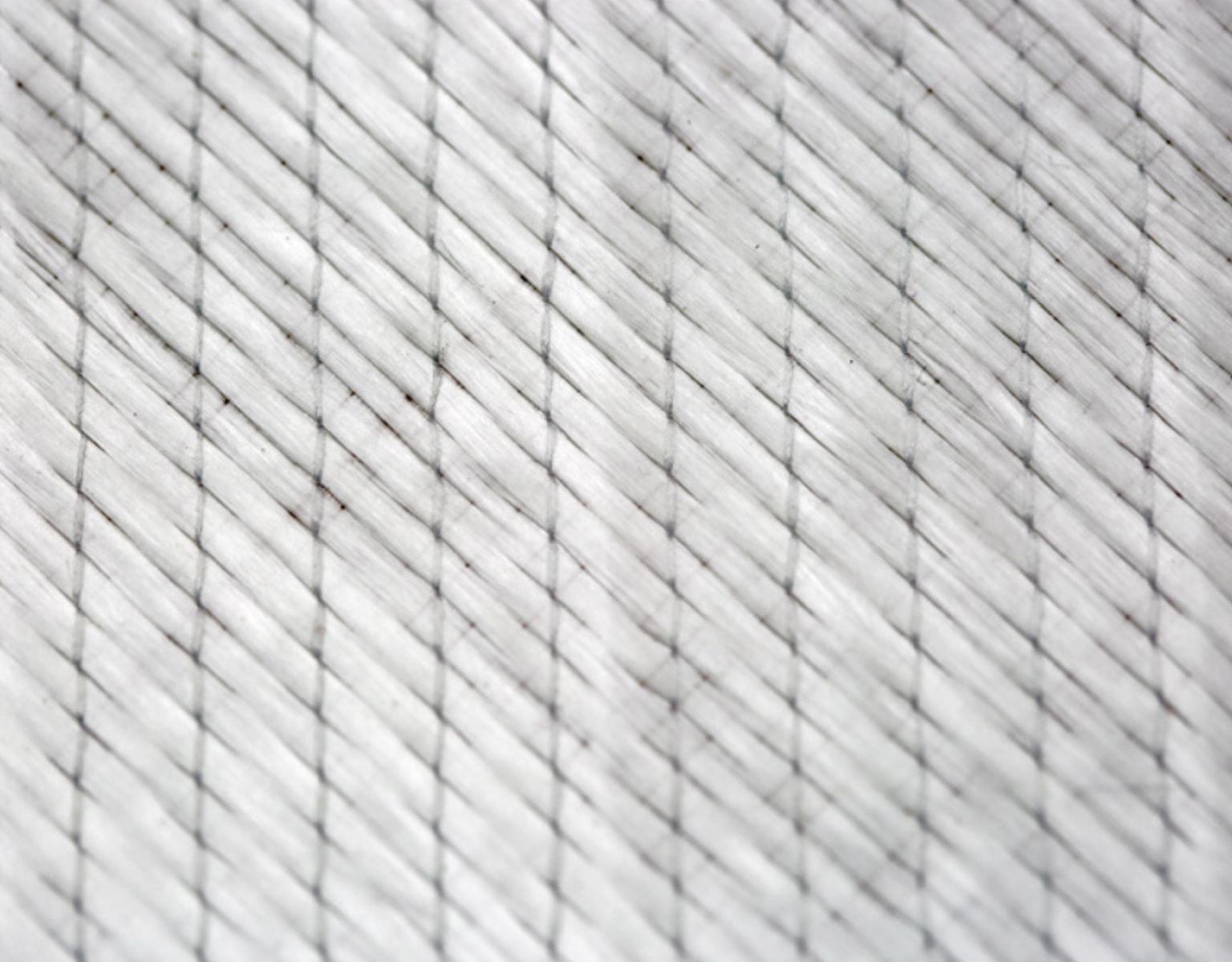

Woven filtration materials are formed through the intertwining of warp and weft yarns. While they offer convenient cleaning, high strength, and long lifespan, their relatively large straight-through pores make achieving high-precision filtration challenging, resulting in relatively high filtration resistance. Knitted filtration materials, on the other hand, can block smaller particles due to internal channel bending but are prone to structural changes and yarn breakage, affecting their lifespan and filtration stability.

Nonwoven filtration materials are widely popular for their simple production processes, high speed, high yield, and low cost. Compared to traditional woven filtration materials, nonwoven materials feature a unique three-dimensional mesh structure with a large internal surface area and high porosity, making them the most commonly used filtration materials currently available.

Woven filtration materials are formed through the intertwining of warp and weft yarns. While they offer convenient cleaning, high strength, and long lifespan, their relatively large straight-through pores make achieving high-precision filtration challenging, resulting in relatively high filtration resistance. Knitted filtration materials, on the other hand, can block smaller particles due to internal channel bending but are prone to structural changes and yarn breakage, affecting their lifespan and filtration stability.

Nonwoven filtration materials are widely popular for their simple production processes, high speed, high yield, and low cost. Compared to traditional woven filtration materials, nonwoven materials feature a unique three-dimensional mesh structure with a large internal surface area and high porosity, making them the most commonly used filtration materials currently available.

Composite filtration materials combine the advantages of multiple materials to provide efficient filtration performance. For example, SMS composite materials combine the excellent filtration performance of meltblown materials with the high strength of spunbond fabrics, while film materials like PTFE film offer uniform pore sizes and high temperature resistance, acid and alkali resistance, and prolonged lifespan.

Fiber raw materials are diverse, including glass fibers, polyimide fibers, quartz fibers, ceramic fibers, and more. These fibers and their composite materials are particularly suitable for high-temperature and corrosion-resistant filtration applications, and have been widely applied in various industries such as power, chemical, and steel, bringing significant economic and environmental benefits.

Composite filtration materials combine the advantages of multiple materials to provide efficient filtration performance. For example, SMS composite materials combine the excellent filtration performance of meltblown materials with the high strength of spunbond fabrics, while film materials like PTFE film offer uniform pore sizes and high temperature resistance, acid and alkali resistance, and prolonged lifespan.

Fiber raw materials are diverse, including glass fibers, polyimide fibers, quartz fibers, ceramic fibers, and more. These fibers and their composite materials are particularly suitable for high-temperature and corrosion-resistant filtration applications, and have been widely applied in various industries such as power, chemical, and steel, bringing significant economic and environmental benefits.

Get In Touch With Us!

To know more about our composite products and solutions, contact our experts! Here is how you can reach us.

Get In Touch With Us!

To know more about our composite products and solutions, contact our experts! Here is how you can reach us.

Popular Composite Materials

Popular Composite Materials

Related Composite Materials Industries

Related Composite Materials Industries

Composites Knowledge Hub

Composites Knowledge Hub