+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Carbon Fiber Multiaxial Fabric

Hybrid Woven Fabric

+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Two-dimensional Braiding Structures

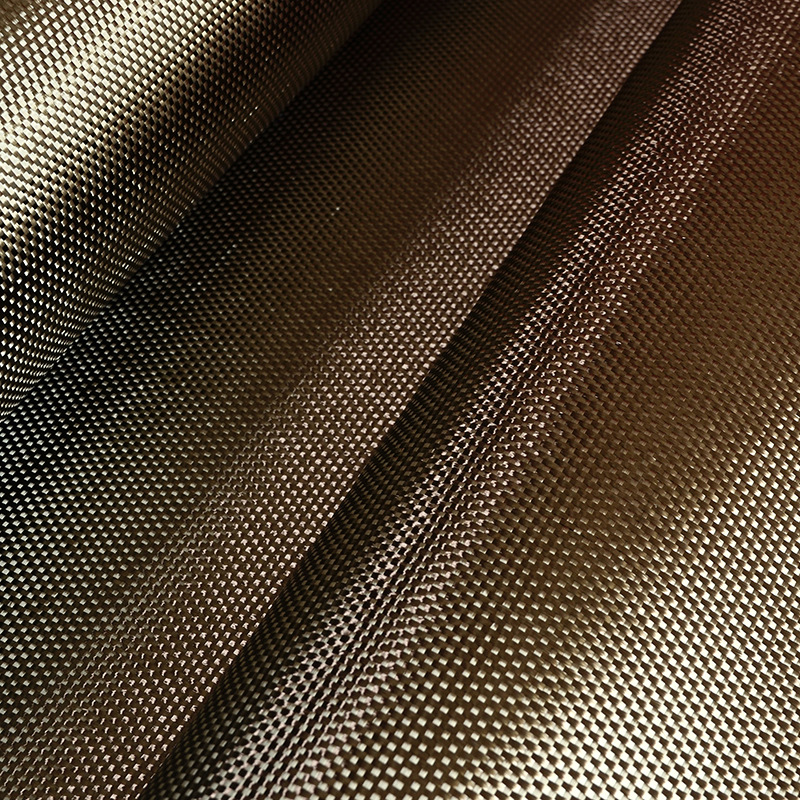

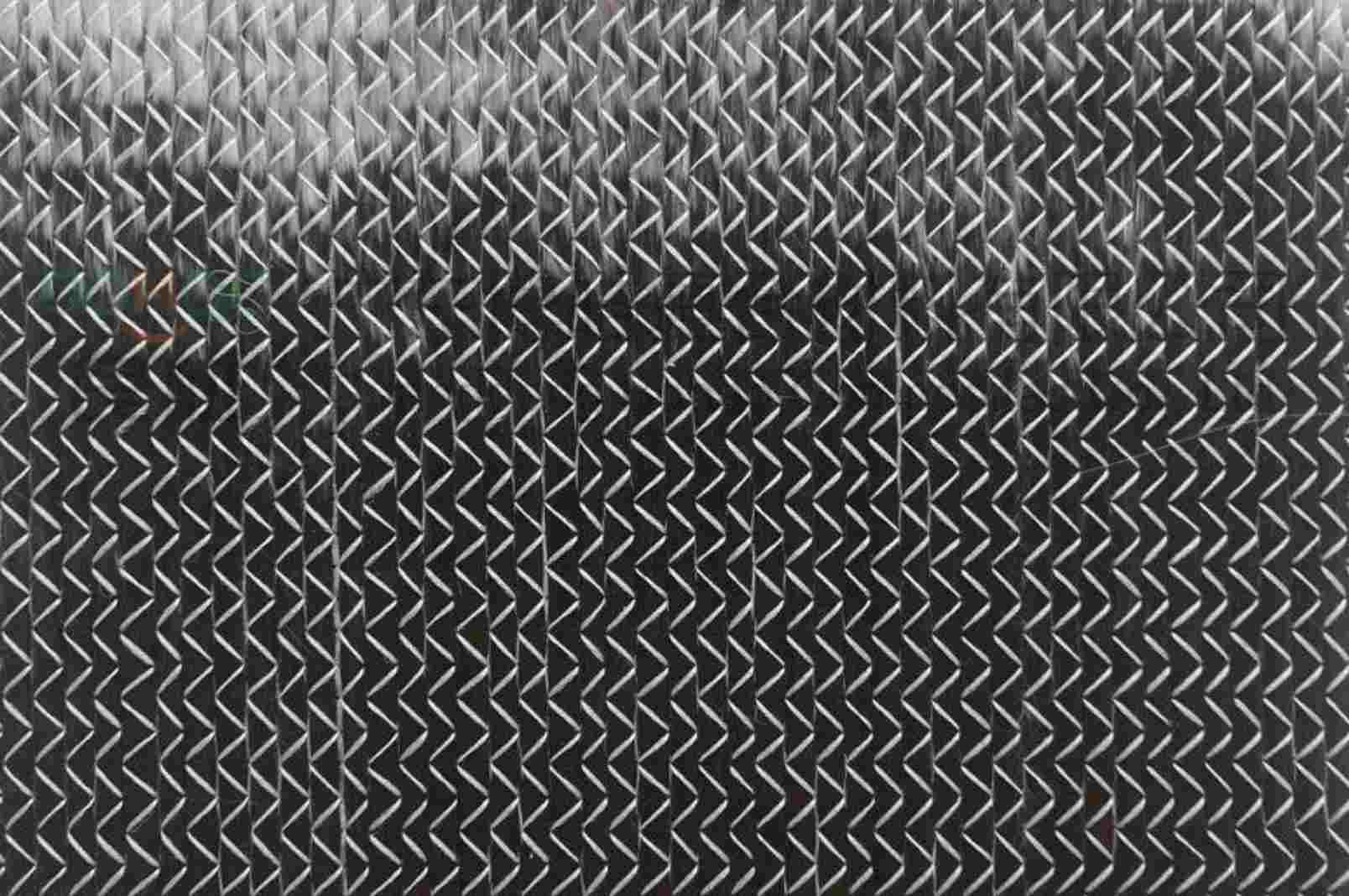

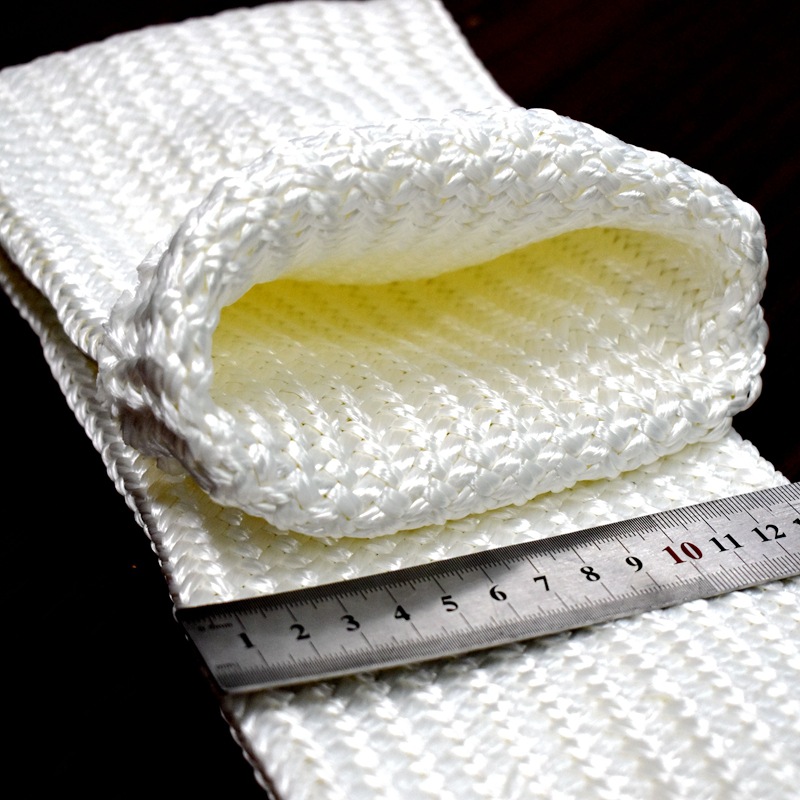

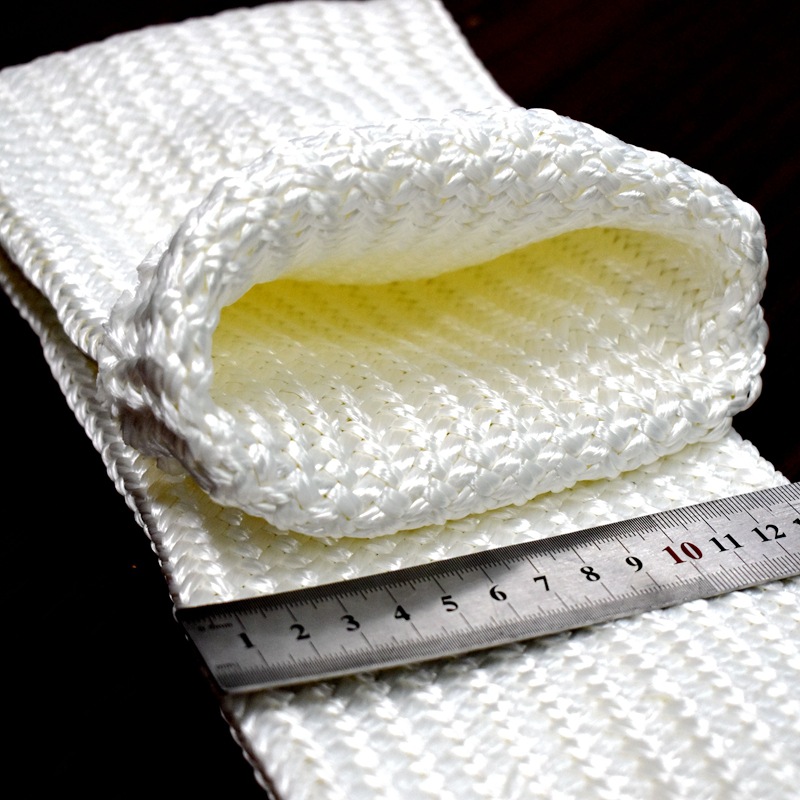

In two-dimensional braiding structures, the thickness of the braided fabric should not exceed three times the diameter of the braiding yarn, which allows for the manufacturing of atypical thin-shell preforms. On the track plate, two sets of braiding yarns in the two-dimensional fabric move in two opposing directions, creating an interlacing angle with the fabric direction at ±α°. Axial performance can be enhanced by incorporating an axial yarn system, as illustrated in Figure 3 (α: braiding angle; h: pitch length).

Three-dimensional Braiding Structures

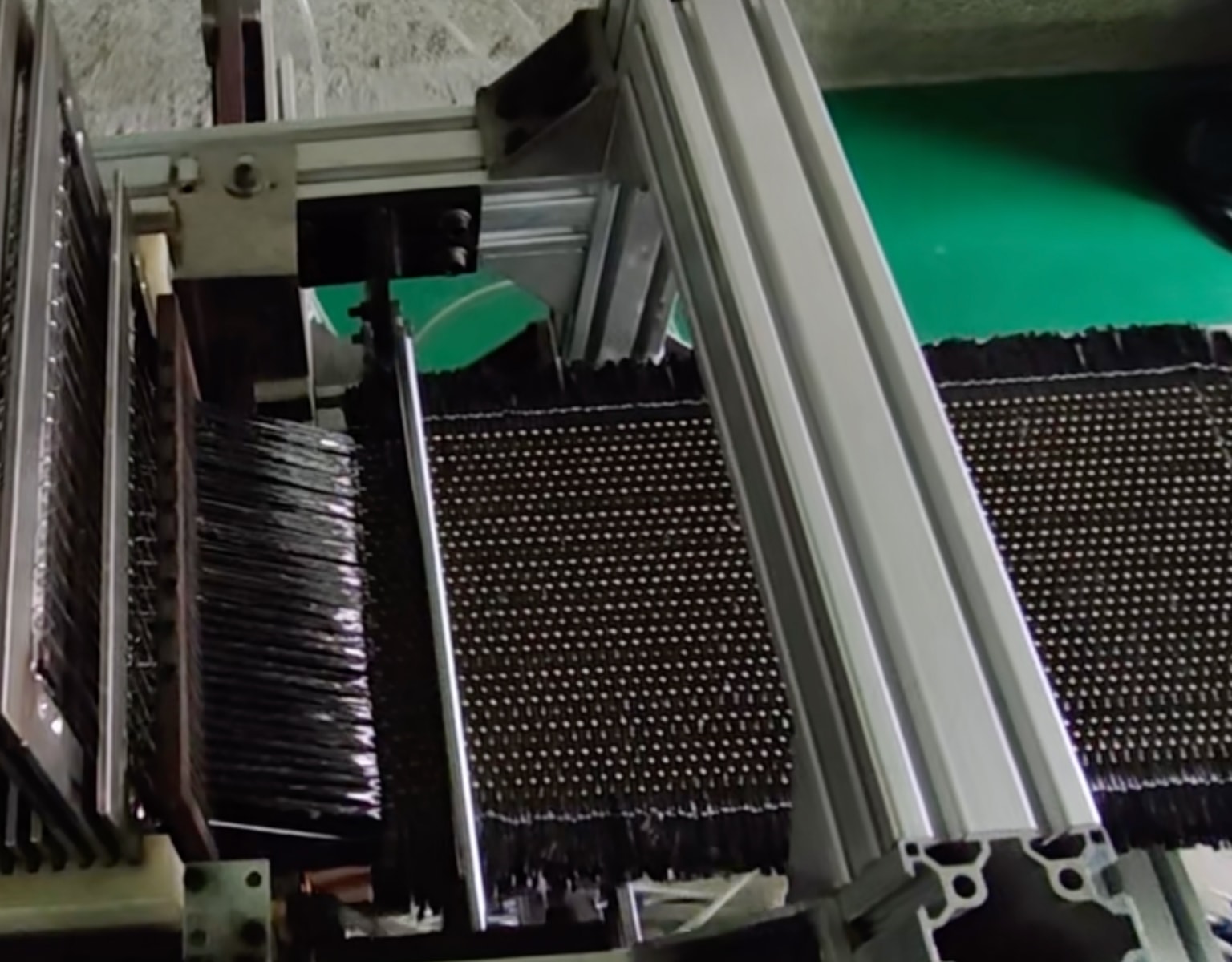

Three-dimensional integral braiding methods include two-step and four-step braiding processes, with square and circular braiding forms. In the two-step braiding process, the yarns in the preforms are oriented in five spatial directions, with a significant proportion of axial yarns. The basic braiding form of the four-step method contains only braiding yarns, but axial yarns can be added. Within the interior space of the fabric, the yarn orientation can be in four directions. By introducing axial yarns in different directions, three-dimensional preforms with five, six, or seven directional braids can be obtained. Three-dimensional braided preforms can be designed with parameters such as braiding angle, node length, and the number of lining yarns, and altering these parameters can change the properties of the composite materials. However, the braiding width of industrial braiding machines on the market is limited, and the braiding speed is not high, which restricts their widespread application.

Three-dimensional Braiding Equipment and Technology

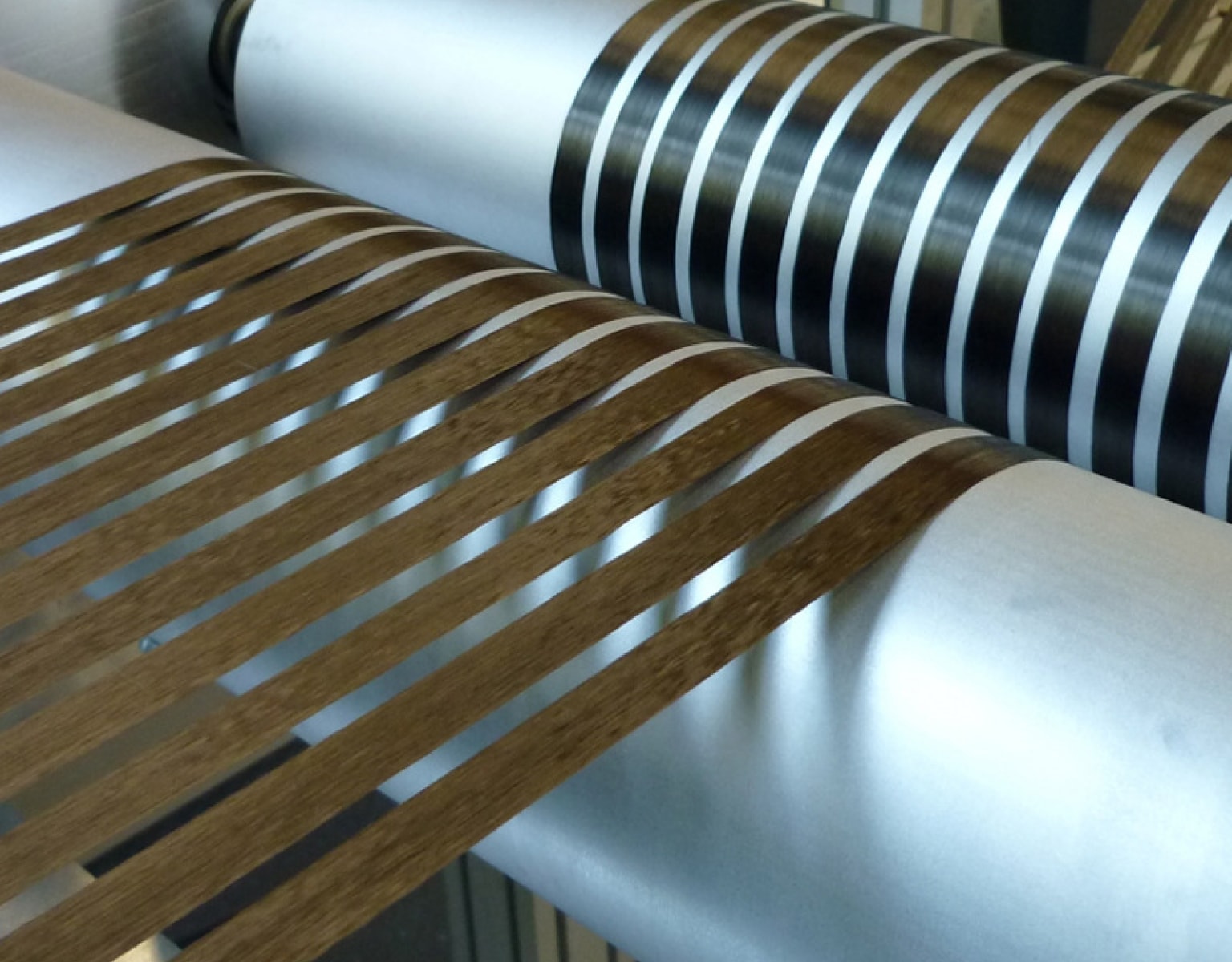

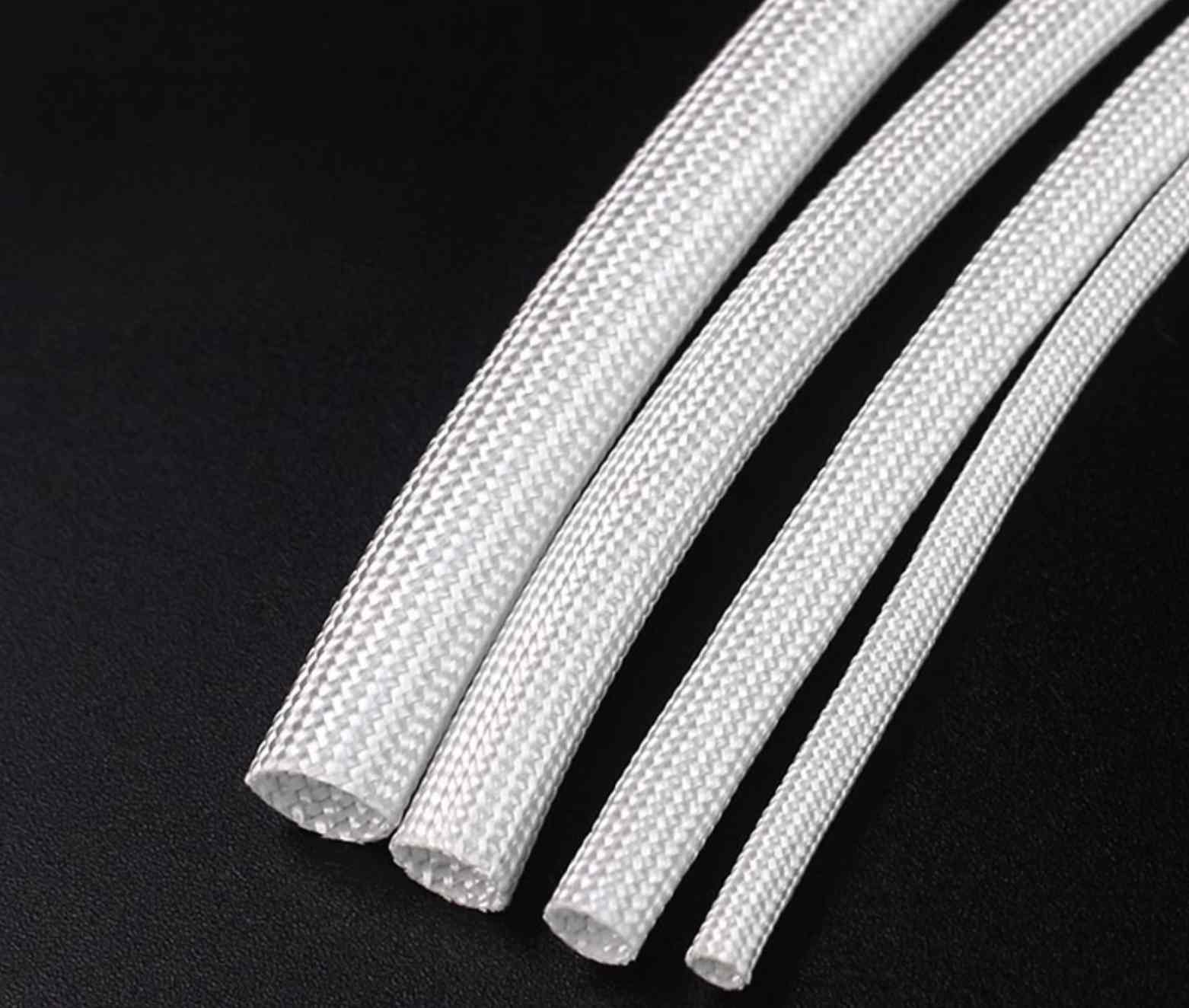

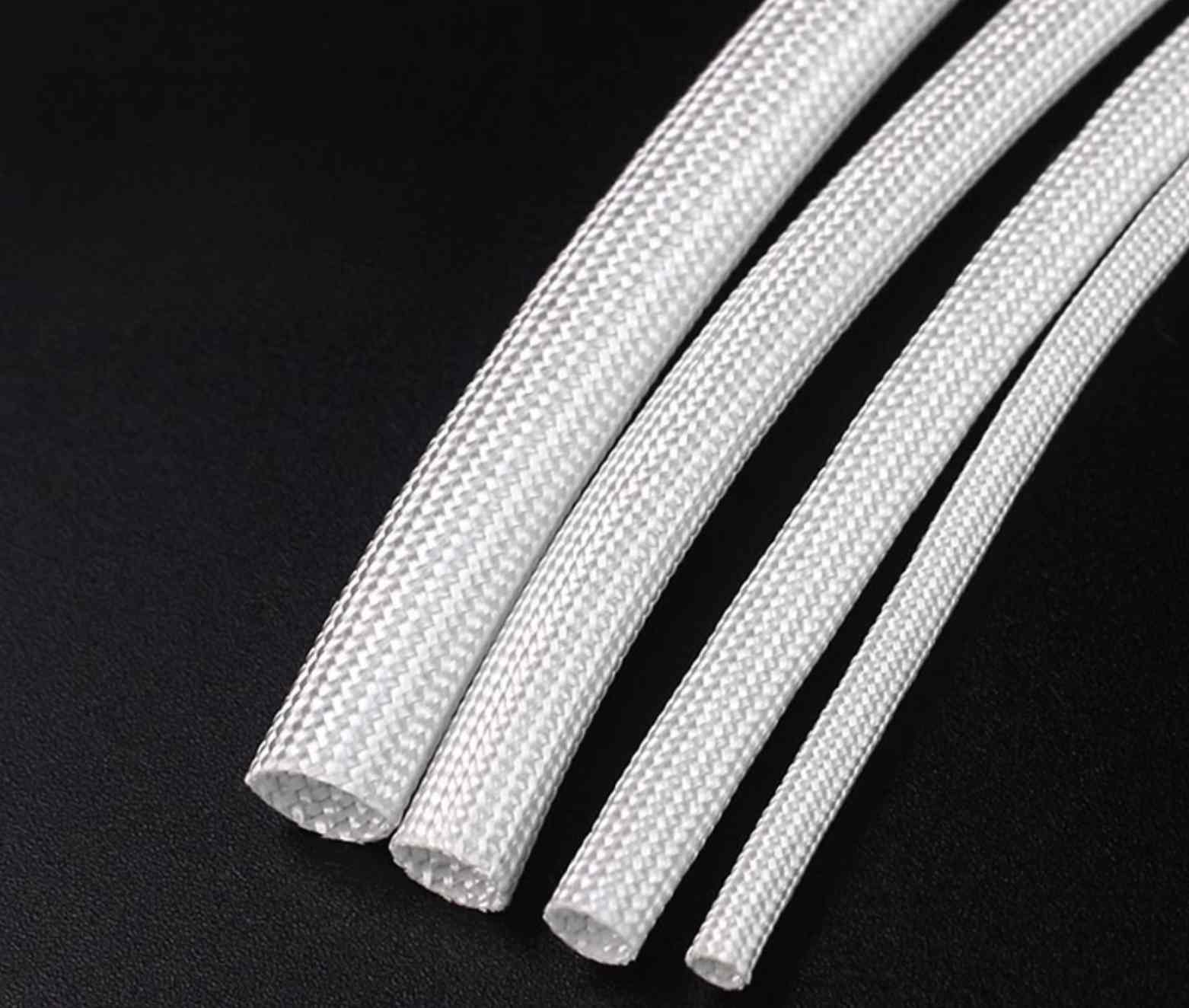

Three-dimensional braided composite materials not only retain the high specific strength and high specific modulus benefits of traditional composite materials but also feature strong structural integrity, resistance to delamination, and resilience to impact damage. In recent years, Xcellent Composites has been involved in the development of intelligent three-dimensional braiding equipment, four-step three-dimensional braiding machines, and associated three-dimensional braided composite material products, capable of braiding high-performance fiber materials into variable cross-sections, thicknesses, and unconventional shapes like panels and tubes.

Two-dimensional Braiding Structures

In two-dimensional braiding structures, the thickness of the braided fabric should not exceed three times the diameter of the braiding yarn, which allows for the manufacturing of atypical thin-shell preforms. On the track plate, two sets of braiding yarns in the two-dimensional fabric move in two opposing directions, creating an interlacing angle with the fabric direction at ±α°. Axial performance can be enhanced by incorporating an axial yarn system, as illustrated in Figure 3 (α: braiding angle; h: pitch length).

Three-dimensional Braiding Structures

Three-dimensional integral braiding methods include two-step and four-step braiding processes, with square and circular braiding forms. In the two-step braiding process, the yarns in the preforms are oriented in five spatial directions, with a significant proportion of axial yarns. The basic braiding form of the four-step method contains only braiding yarns, but axial yarns can be added. Within the interior space of the fabric, the yarn orientation can be in four directions. By introducing axial yarns in different directions, three-dimensional preforms with five, six, or seven directional braids can be obtained. Three-dimensional braided preforms can be designed with parameters such as braiding angle, node length, and the number of lining yarns, and altering these parameters can change the properties of the composite materials. However, the braiding width of industrial braiding machines on the market is limited, and the braiding speed is not high, which restricts their widespread application.

Three-dimensional Braiding Equipment and Technology

Three-dimensional braided composite materials not only retain the high specific strength and high specific modulus benefits of traditional composite materials but also feature strong structural integrity, resistance to delamination, and resilience to impact damage. In recent years, Xcellent Composites has been involved in the development of intelligent three-dimensional braiding equipment, four-step three-dimensional braiding machines, and associated three-dimensional braided composite material products, capable of braiding high-performance fiber materials into variable cross-sections, thicknesses, and unconventional shapes like panels and tubes.

Popular Composite Materials

Popular Composite Materials

Related Composite Materials Capabilities

Related Composite Materials Capabilities

Composites Knowledge Hub

Composites Knowledge Hub

Tel:

86-13732282311

E-mail:

merlin@xcellentcomposites.com

Copyright © Hangzhou Xcellent Composites Limited. All Rights Reserved.