+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Why Biaxial Carbon Fiber Cloth is Essential

Carbon fiber cloth has long been admired for its exceptional strength-to-weight ratio and high-performance applications across various industries. Among the different types of carbon fiber fabrics, biaxial carbon fiber cloth stands out for its unique properties, versatility, and critical role in composite manufacturing. Whether you're working in aerospace, automotive, marine, or sports equipment, understanding the importance of biaxial carbon fiber cloth can transform how you design, create, and innovate.

In this blog, we will delve into why biaxial carbon fiber cloth is essential in modern engineering, its advantages over other types of carbon fabric cloth, and how it is revolutionizing industries that demand high-strength, lightweight materials.

Understanding Biaxial Carbon Fiber Cloth

What is Carbon Fiber Cloth?

Before diving into biaxial carbon fiber cloth, it’s important to understand what carbon fiber fabric is in general. Carbon fiber cloth is made from carbon filaments, which are derived from a polymer precursor that undergoes a process called carbonization. The fibers are extremely thin, and when woven into a cloth, they form a fabric that retains the remarkable properties of carbon fiber: high strength, low weight, and exceptional resistance to heat and chemicals. Carbon fiber fabric is typically used as a reinforcement material in composite structures, where it is combined with a resin matrix to form a strong, lightweight composite material.

What Makes Biaxial Carbon Fiber Cloth Different?

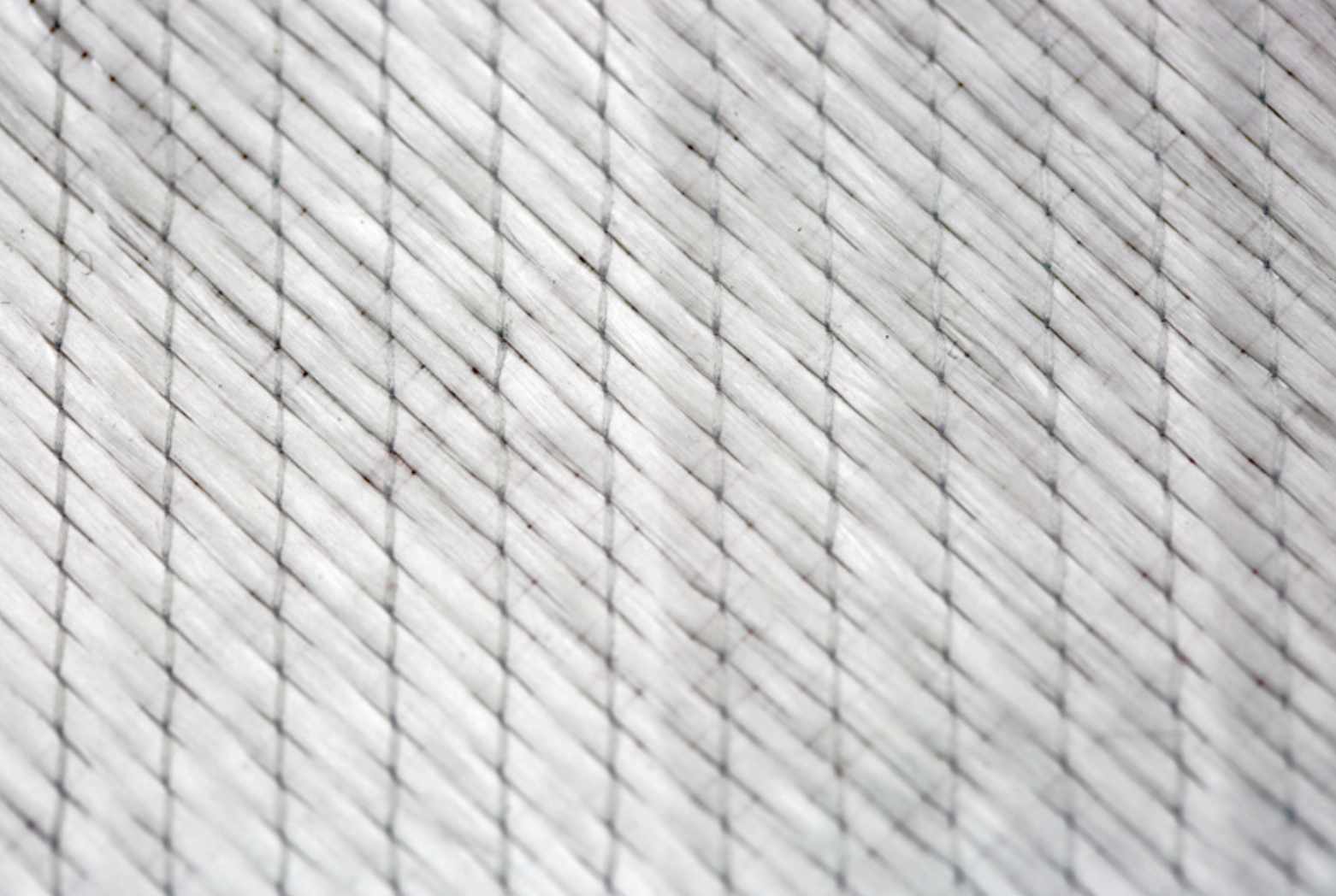

Biaxial carbon fiber cloth refers to a fabric made from carbon fibers arranged in two primary directions, typically at 0° and 90° angles to each other. The fibers are woven together in a crisscross pattern, which gives the fabric strength in both directions. This is in contrast to unidirectional carbon fiber cloth, where the fibers are aligned in a single direction, making it stronger in one direction but weaker in others. Biaxial carbon fiber cloth provides a more balanced strength distribution, making it particularly useful in applications where multi-directional forces are involved.

In essence, biaxial carbon fiber cloth offers a versatile, multi-directional strength that is indispensable in industries where high performance is critical. The 0°/90° weave pattern is the most common, but manufacturers can also produce biaxial cloth with different angles, such as 45°/45°, depending on the needs of the application.

The Key Advantages of Biaxial Carbon Fiber Cloth

1.Enhanced Strength and Durability

The primary reason why biaxial carbon fiber cloth is essential is its impressive strength and durability. The fabric's unique weave of fibers at 0° and 90° angles means it can handle forces applied from multiple directions. This is especially useful in applications where the material is subjected to dynamic stresses, such as vibrations, impacts, or torsional forces. In comparison, unidirectional carbon fiber cloth is optimal for applications where forces act in a single direction, but it’s not as effective at handling multi-directional stress.

For example, in the automotive industry, biaxial carbon fiber cloth is used in high-performance car parts such as chassis and body panels. These components are exposed to a wide range of stresses, including torsional forces and impact forces during crashes. The biaxial weave ensures that these parts can absorb and distribute stress efficiently, enhancing their durability and safety.

In aerospace, biaxial carbon fiber cloth is used in wings, fuselages, and engine components, where the material must endure constant stress from air pressure, turbulence, and extreme temperatures. The ability of biaxial cloth to resist fatigue and maintain its integrity under stress is what makes it indispensable for both commercial and military aviation applications.

2.Lightweight Nature

One of the hallmark features of carbon fiber materials, including biaxial carbon fiber cloth, is their extremely low weight relative to their strength. This is a key advantage in industries where reducing weight is a critical factor, such as aerospace, automotive, and marine. The lighter the material, the less fuel it requires to move, and the faster it can accelerate or decelerate.

In the aerospace industry, weight reduction is directly tied to fuel efficiency and payload capacity. Aircraft manufacturers are constantly looking for ways to reduce the weight of an aircraft while maintaining or improving its structural integrity. By incorporating biaxial carbon fiber cloth into their designs, they can achieve this balance. For instance, the fuselage of an aircraft might be made of a composite material that includes carbon fabric cloth, helping to reduce the overall weight while providing the strength needed to withstand the forces of flight.

In motorsports, biaxial carbon fiber cloth is used extensively in race car construction, particularly in the body panels and internal reinforcement structures. A lighter car accelerates faster, handles better, and consumes less fuel, giving race teams a competitive edge. The combination of low weight and high strength allows engineers to design vehicles that are not only faster but also safer in high-impact situations.

3.Flexibility in Application

Another reason why biaxial carbon fiber cloth is essential is its incredible versatility. The fabric can be used in a wide range of applications, from aerospace to sporting goods, because it can be molded into complex shapes. The fabric’s flexibility makes it ideal for creating components with intricate geometries that are lightweight yet strong.

For instance, in the automotive industry, biaxial carbon fabric cloth can be used to create lightweight, high-strength components such as car doors, roof panels, and suspension parts. These parts need to be both robust and lightweight to ensure safety and performance, and the biaxial weave provides the perfect balance of both qualities.

In sports, products like high-performance bicycles, surfboards, and even golf clubs are often made with carbon fiber composites. The biaxial weave helps create strong yet flexible designs that perform well under pressure while remaining light enough for competitive advantage. The ability to precisely control the fabric's properties allows manufacturers to create customized solutions for each specific application.

4.Superior Corrosion Resistance

Unlike metals, which can corrode over time when exposed to moisture or harsh chemicals, carbon fabric cloth is highly resistant to corrosion. This makes biaxial carbon fiber cloth an ideal material for applications in environments where exposure to water, salt, or chemicals is a concern. Its corrosion resistance contributes to its long lifespan and makes it easier to maintain.

In marine environments, for example, biaxial carbon fiber cloth is often used in the construction of boat hulls, masts, and other components exposed to saltwater. Saltwater can quickly degrade metals like aluminum and steel, but carbon fiber composites made with biaxial carbon fiber cloth maintain their strength and integrity even after prolonged exposure.

Similarly, in chemical processing or oil and gas industries, carbon fiber composites are used to create pipes, tanks, and other equipment that need to withstand exposure to corrosive substances. By using biaxial carbon fiber cloth, manufacturers can ensure that these components perform optimally over time without needing frequent replacements or repairs.

Biaxial Carbon Fiber Cloth vs. Other Carbon Fabrics

Biaxial vs. Unidirectional Carbon Fiber Cloth

When comparing biaxial carbon fiber cloth to unidirectional carbon fiber cloth, it’s important to consider how each fabric behaves under stress. Unidirectional carbon fiber cloth is made up of fibers that run in a single direction, typically along the length of the fabric. This makes it extremely strong along the fiber axis but much weaker when forces act perpendicular to the fibers.

In contrast, biaxial carbon fiber cloth offers strength in two directions (0° and 90°), making it ideal for applications where forces act from multiple directions. For example, in a race car chassis, parts like the frame might require unidirectional carbon fiber for maximum strength along the length of the structure, while body panels that experience forces from multiple directions, like side impacts, benefit from biaxial carbon fiber cloth.

Ultimately, the choice between biaxial and unidirectional cloth depends on the nature of the application. Biaxial carbon fiber cloth offers versatility and is often used where forces act in multiple directions, while unidirectional cloth is perfect for unidirectional load-bearing applications.

Biaxial vs. Tri-axial Carbon Fiber Cloth

Tri-axial carbon fiber cloth takes the strength of biaxial cloth a step further by introducing a third fiber orientation, often at a 45°angle. This increases the material’s strength in three dimensions, making it ideal for extremely demanding applications, such as in aerospace or heavy-duty automotive components.

However, biaxial carbon fiber cloth is typically more affordable and easier to handle than tri-axial cloth. For most applications that require multi-directional strength but do not demand the highest possible performance, biaxial carbon fiber cloth strikes the right balance between cost, performance, and ease of use.

Applications Where Biaxial Carbon Fiber Cloth is Essential

1.Aerospace Industry

The aerospace industry demands materials that are not only strong and lightweight but also capable of withstanding extreme environmental conditions. Biaxial carbon fiber cloth is essential in meeting these requirements. Aircraft, whether commercial or military, are designed with components made from composite materials that incorporate carbon fiber fabrics. Wings, fuselages, and control surfaces are just a few examples of the critical parts that rely on biaxial carbon fiber cloth for their performance and structural integrity.

2.Automotive Industry

In the automotive sector, performance and safety are paramount. Biaxial carbon fiber cloth is used in various high-performance components, including body panels, chassis, and suspension systems. The fabric’s combination of strength, light weight, and durability allows for improved fuel efficiency, better handling, and enhanced crash resistance.

3.Marine Industry

Biaxial carbon fiber cloth plays a vital role in marine applications, where components are exposed to corrosive saltwater and high stresses. Boat hulls, masts, and other key structures are often made with carbon fabric cloth, providing a lightweight, durable, and corrosion-resistant solution for modern vessels.

4.Sports Equipment

In the sports industry, high-performance equipment requires materials that are both lightweight and durable. Biaxial carbon fiber cloth is used in the manufacture of bicycles, surfboards, and even sporting accessories like golf clubs. The material’s versatility and strength allow athletes to perform at their best, knowing that their equipment is built for speed, strength, and longevity.

Conclusion

Biaxial carbon fiber cloth is a crucial material in a wide range of industries due to its unique blend of strength, lightness, and versatility. Whether used in aerospace, automotive, marine, or sports applications, it provides a competitive advantage that helps manufacturers create high-performance products with improved durability and safety. The fabric’s ability to handle multi-directional stress, combined with its low weight and superior corrosion resistance, ensures that biaxial carbon fiber cloth will continue to be an essential material in engineering and manufacturing.

Read More: A Beginner's Guide to Working with Woven Fiberglass Cloth

Popular Composite Materials

Popular Composite Materials

Composites Knowledge Hub

Composites Knowledge Hub