+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

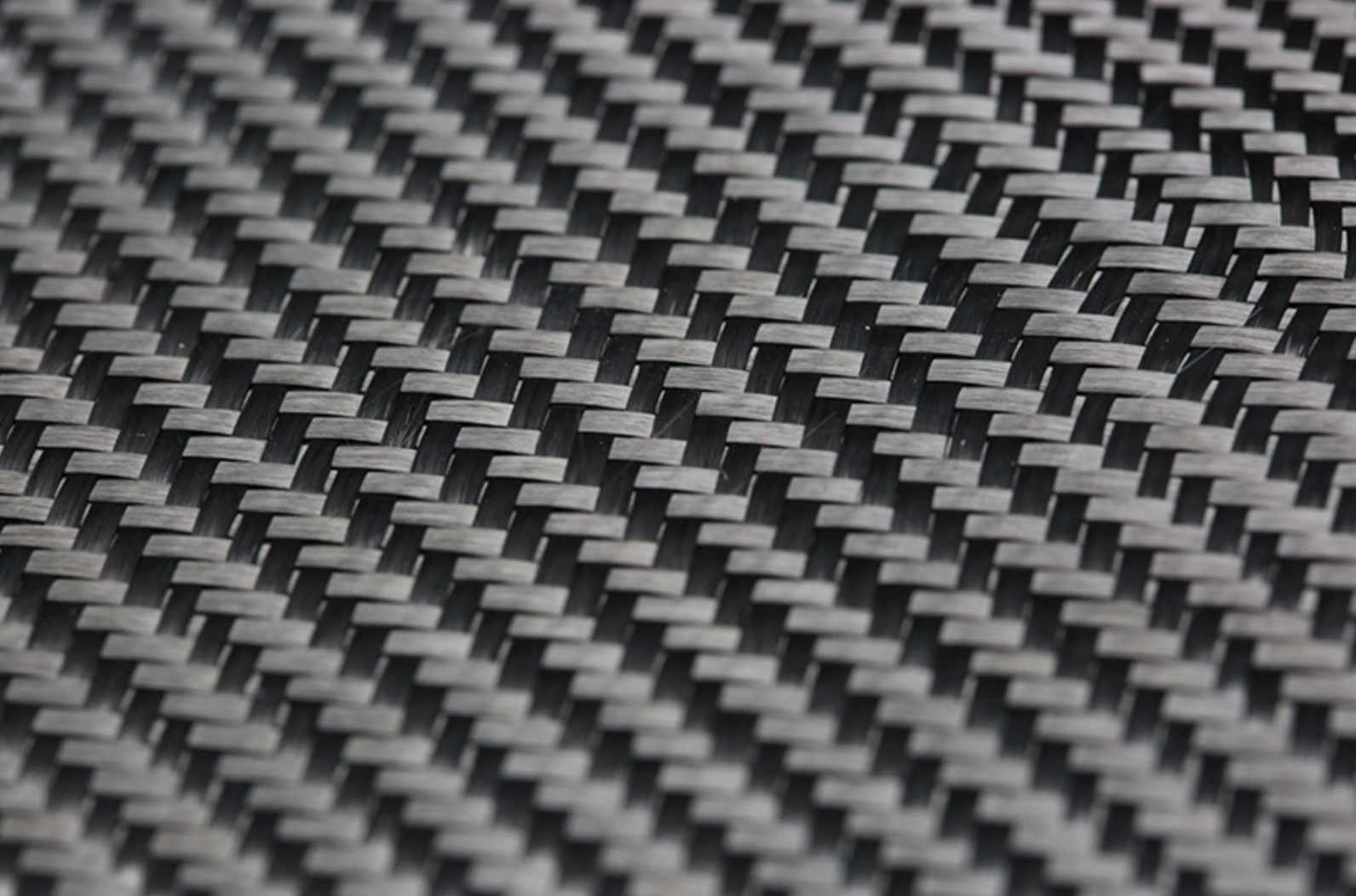

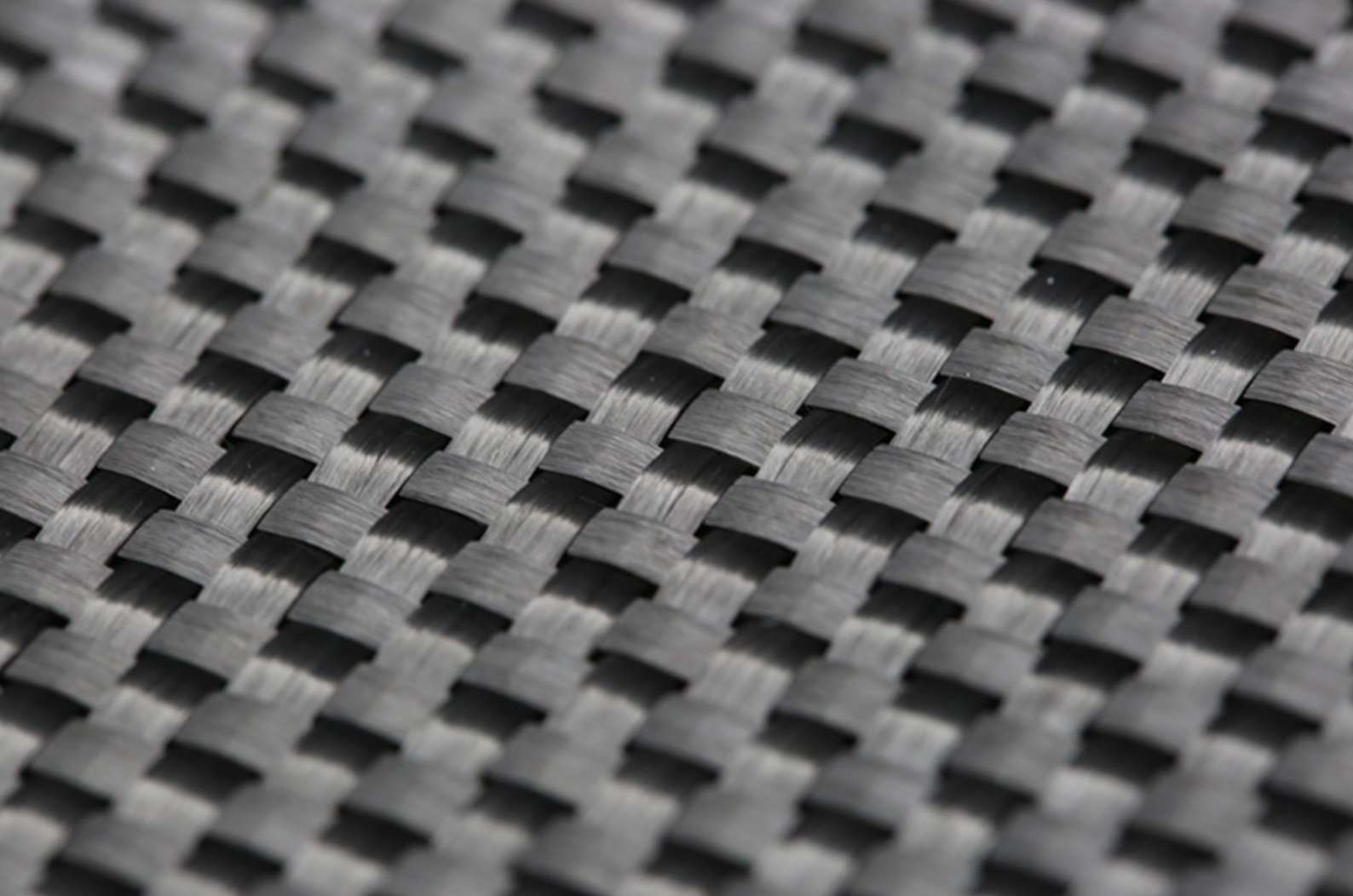

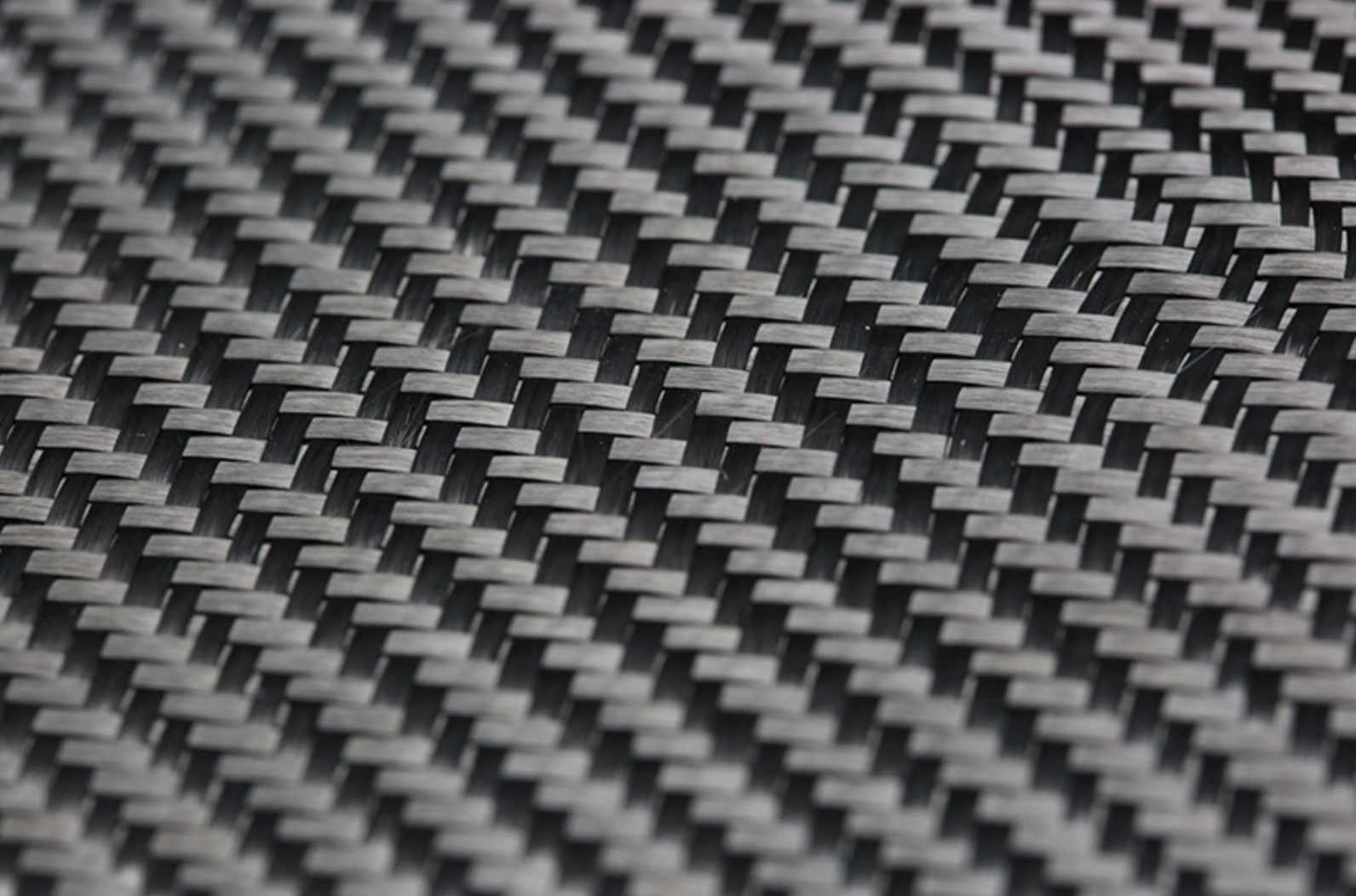

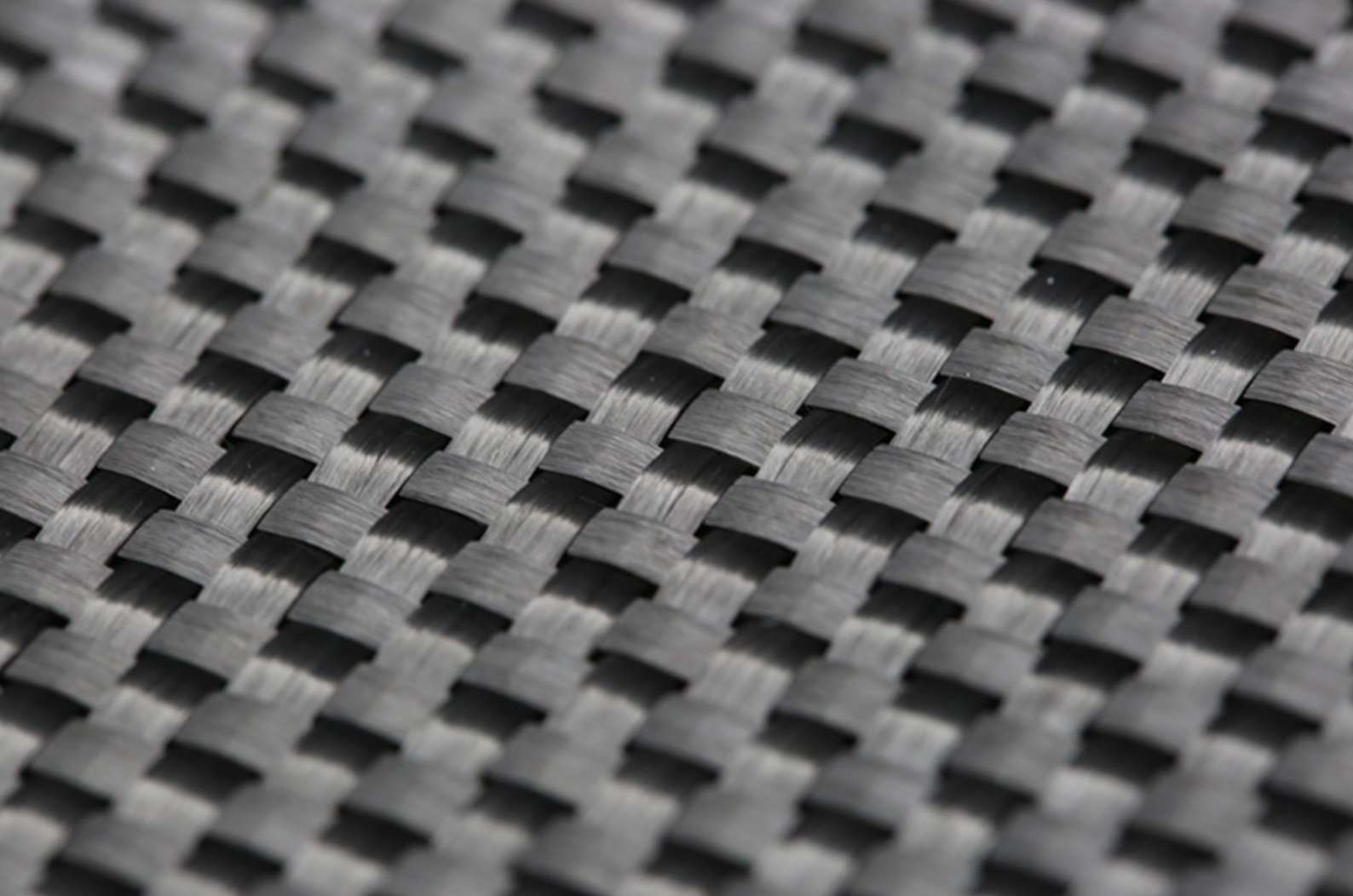

Carbon Fiber Woven Fabric

Features of Carbon Fiber Woven Fabric

| 01. | Clear texture: | The fabric has a well-defined and distinct texture, making it visually and tactically pleasing. Clear texture means the patterns or weaves in the fabric are easily recognizable and distinct. This clarity in texture can enhance the aesthetic appeal of the material and contribute to its overall quality. In practical terms, clear texture helps in creating precise and crisp designs, whether for fashion, upholstery, or other applications. |

| 02. | No fuzz: | The carbon fiber woven fabric is free from loose fibers or lint that can create a fuzzy or pilled appearance.This quality is crucial for maintaining the neat and polished look of the fabric. Fabrics without fuzz are often more durable and require less maintenance, as they don’t shed fibers over time. This characteristic is particularly valued in high-quality textiles, as it ensures the fabric remains smooth and clean-looking after repeated use and washing. |

| 03. | No color difference: | The fabric’s color consistency across its entire surface. No color difference means that the dyeing process was uniform, resulting in a fabric with a consistent color without any streaks, spots, or variations. This is important for aesthetic reasons, ensuring that the final product looks cohesive and professionally made. For products like uniforms or designer clothing, consistent color is crucial for maintaining brand standards and visual appeal. |

| 04. | Smooth fabric surface: | The textile feels even and polished to the touch, without bumps, wrinkles, or irregularities. This feature is often a sign of high-quality manufacturing and finishing processes. A smooth surface enhances the tactile experience and can also improve the appearance of the fabric, making it look more refined and sophisticated. This quality is especially important for garments that are worn close to the skin or for fabrics used in high-end interior design. |

| 05. | Uniform warp and weft density: | Warp and weft refer to the two sets of threads that are woven together to create fabric. Uniform warp and weft density means that these threads are evenly spaced and consistent throughout the entire piece of fabric. This evenness contributes to the fabric’s strength, durability, and overall quality. Uniform density ensures that the fabric has a consistent texture and appearance, which is essential for both functional and aesthetic purposes. It also helps prevent issues like stretching or sagging over time. |

| 06. | Stable mechanical properties: | The carbon fiber woven fabric's ability to maintain its physical characteristics, such as strength, elasticity, and dimensional stability, under various conditions. Stable mechanical properties mean the fabric won't easily stretch out of shape, tear, or lose its integrity with regular use and laundering. This stability is crucial for ensuring the longevity and reliability of the fabric, making it suitable for applications where durability and consistent performance are required, such as in workwear or upholstery. |

Learn about Twill Weave Carbon Fiber

Get Price of Composite Materials

Get Price of Composite Materials

E-mail:

Address:

NO.61, XIANGYANGJIAYUAN, XIAOSHAN, HANGZHOU, CHINA

Related Composite Materials

Related Composite Materials

Carbon Fiber Spread Tow Fabric

Spread tow fabric is a fabric woven using spread yarn and is a new type of carbon fiber reinforced material. This fabric has characteristics such as low yarn bending, low surface density, good lay-flat properties, and high design flexibility.

1414 Aramid Fiber Woven Fabrics

Xcellent Composites produces aramid fabrics primarily using para-aramid 1414, and can design them into various fabric structures such as plain, twill, or satin weave, as well as more complex weaving patterns to adjust their mechanical properties and aesthetic characteristics.

Fiberglass Woven Fabric

Xcellent Composites produces a series of fiberglass woven fabrics designed for various applications, including fabrics for electronic printed circuit boards, expansion fabrics, and filter fabrics.

Basalt Fiber Woven Fabric

Basalt mesh fabric is made by twisting basalt fibers and then applying a resin coating. The mesh structure enhances the fabric's stability and durability, making it suitable for reinforcing concrete and road repairs.

Carbon Fiber Spread Tow Fabric

Spread tow fabric is a fabric woven using spread yarn and is a new type of carbon fiber reinforced material. This fabric has characteristics such as low yarn bending, low surface density, good lay-flat properties, and high design flexibility.

1414 Aramid Fiber Woven Fabrics

Xcellent Composites produces aramid fabrics primarily using para-aramid 1414, and can design them into various fabric structures such as plain, twill, or satin weave, as well as more complex weaving patterns to adjust their mechanical properties and aesthetic characteristics.

Fiberglass Woven Fabric

Xcellent Composites produces a series of fiberglass woven fabrics designed for various applications, including fabrics for electronic printed circuit boards, expansion fabrics, and filter fabrics.

Basalt Fiber Woven Fabric

Basalt mesh fabric is made by twisting basalt fibers and then applying a resin coating. The mesh structure enhances the fabric's stability and durability, making it suitable for reinforcing concrete and road repairs.

Composites Knowledge Hub

Composites Knowledge Hub