+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

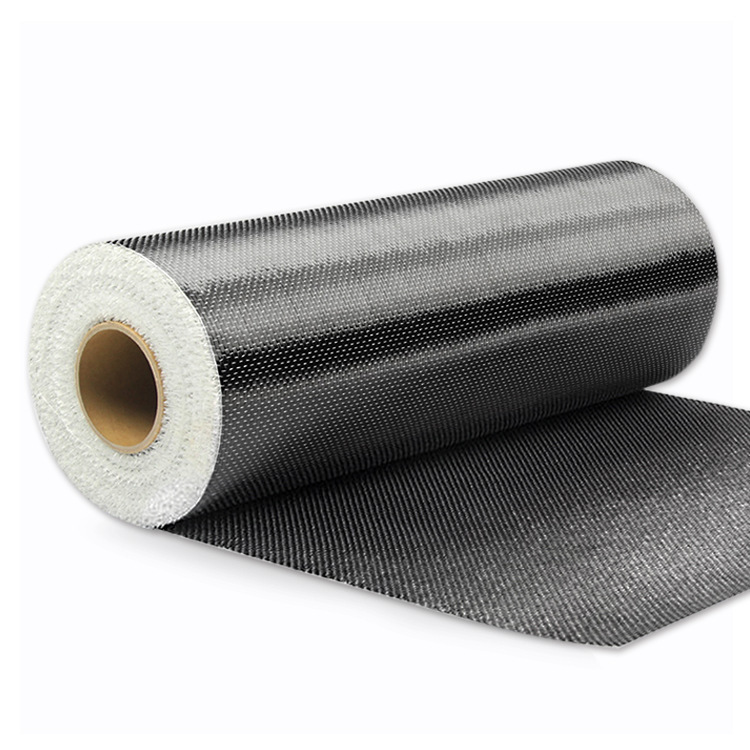

What Is Woven Carbon Fiber Cloth?

Woven carbon fiber cloth is a high-performance material made from carbon fibers interlaced in specific patterns to create a fabric-like structure. It is widely recognized for its exceptional strength-to-weight ratio, rigidity, and durability, making it an essential material in industries like aerospace, automotive, sports, and renewable energy. This material is also commonly referred to as woven carbon fiber, carbon woven fabric, or woven carbon fabric, depending on the application or industry context.

What is Carbon Fibers

Carbon fibers are thin, strong fibers primarily composed of carbon atoms. These fibers are produced through the controlled oxidation, carbonization, and graphitization of precursor materials, typically polyacrylonitrile (PAN) or pitch. The result is a lightweight material with remarkable mechanical properties, including high tensile strength, stiffness, and thermal resistance.

How Woven Carbon Fiber Cloth Is Made

Woven carbon fiber cloth is created by weaving carbon fiber tows (bundles of fibers) into specific patterns using a loom. This process also applies to other forms, such as carbon woven fabric and woven carbon fabric, which are tailored for diverse applications. Common weaving patterns include:

-

Plain Weave

A simple over-and-under pattern that provides balanced strength and stability. It is the most commonly used weave for general applications. -

Twill Weave

Features a diagonal pattern, offering enhanced drapability and a smoother surface. This is ideal for complex shapes and aesthetically appealing applications. -

Satin Weave

Provides a high degree of flexibility and a smoother finish, often used in decorative or cosmetic applications.

Each weave type has unique characteristics suited for specific applications, depending on the desired balance of strength, flexibility, and appearance.

Key Properties of Woven Carbon Fiber Cloth

-

High Strength-to-Weight Ratio

Woven carbon fiber cloth is significantly stronger than steel or aluminum while being much lighter, making it ideal for weight-sensitive applications. -

Rigidity and Dimensional Stability

Its stiffness and resistance to deformation under stress make it suitable for structural applications requiring high rigidity. -

Thermal and Chemical Resistance

Carbon fiber is highly resistant to extreme temperatures and chemical corrosion, ensuring longevity in harsh environments. -

Fatigue Resistance

The material withstands cyclic stresses over time, maintaining performance even under repeated loading. -

Customizability

Woven carbon fiber, carbon woven fabric, and woven carbon fabric can be tailored with different weave patterns, fiber orientations, and resin systems to meet specific performance requirements.

Applications of Woven Carbon Fiber Cloth

-

Aerospace

Used in aircraft and spacecraft components to reduce weight and improve fuel efficiency without compromising strength. -

Automotive

Found in high-performance vehicles for lightweight structural parts, body panels, and interior components. -

Sports Equipment

Integrated into products like bicycles, tennis rackets, and racing helmets for enhanced performance and durability. -

Renewable Energy

Used in wind turbine blades and other components for its combination of lightness and strength. -

Marine Industry

Ideal for constructing lightweight and durable boat hulls and masts.

Advantages Over Alternative Materials

Woven carbon fiber cloth outperforms traditional materials like metals and fiberglass in terms of weight savings, strength, and corrosion resistance. Variants like carbon fiber woven fabric and woven carbon fabric provide engineers and designers with even more options to optimize performance across a range of demanding applications.

What is the Difference Between Woven Carbon Fiber and Forged Carbon Fiber?

Woven Carbon Fiber

- Structure: Woven carbon fiber consists of long carbon filaments that are interlaced into a specific pattern, such as plain weave, twill, or satin.

- Appearance: It has a uniform and aesthetically pleasing pattern, often chosen for its visual appeal.

- Properties: Known for its high strength and stiffness in specific directions due to the alignment of the fibers. The weaving process ensures consistency and predictability in mechanical performance.

- Applications: Commonly used in aerospace, automotive, sports equipment, and high-performance parts where lightweight and directional strength are crucial.

Forged Carbon Fiber

- Structure: Forged carbon fiber is made from chopped or randomly oriented carbon fiber strands combined with resin and molded under high pressure.

- Appearance: It has a unique, marble-like texture, different from the regular woven appearance.

- Properties: Offers good isotropic properties (uniform strength in all directions) but generally lower stiffness and strength than woven carbon fiber due to the randomness of fiber orientation.

- Applications: Used in components where aesthetics, complex shapes, or cost-effectiveness is prioritized, such as watch cases, automotive parts, and fashion accessories.

How Much Does 1 Kg of Carbon Fiber Cost?

The cost of 1 kg of carbon fiber varies significantly depending on the type, grade, and production process:

- Standard-Grade Woven Carbon Fiber: Approximately $20–$50 per kilogram, often used in industrial and recreational applications.

- High-Grade Aerospace Carbon Fiber: Can cost $80–$300+ per kilogram due to stricter quality requirements and higher performance specifications.

- Forged Carbon Fiber: Typically $50–$100 per kilogram, as it involves additional processing of chopped fibers but is less expensive than high-grade woven types.

Conclusion

Woven carbon fiber cloth is a revolutionary material that combines cutting-edge technology with unmatched performance characteristics. Its adaptability, durability, and superior mechanical properties continue to drive innovation across multiple industries. Whether in aerospace or sports, woven carbon fiber cloth remains a cornerstone of modern engineering and design.

Popular Composite Materials

Popular Composite Materials

Composites Knowledge Hub

Composites Knowledge Hub