+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

Ceramic Fiber

Ceramic Fiber

Ceramic Fiber

Ceramic fibers, made from high-purity alumina, silica, and other minerals through high-temperature melting processes, are refractory materials known for their excellent high-temperature performance and thermal stability in extreme environments. These lightweight and durable fibers can be processed into various textile forms, such as blankets, boards, papers, ropes, and woven fabrics.

Xcellent Composites' carefully designed insulation ceramic fiber products offer outstanding thermal insulation and low thermal conductivity, making them widely used in industries such as metallurgy, chemical engineering, power generation, and aerospace. Our ceramic fiber cloth and textile is a preferred solution for high-temperature industrial applications due to their durability and versatility. Xcellent Composites continuously seeks technological innovation, dedicated to developing more efficient ceramic fiber products to meet the stringent demands of the global market for advanced refractory materials.

Ceramic fibers, made from high-purity alumina, silica, and other minerals through high-temperature melting processes, are refractory materials known for their excellent high-temperature performance and thermal stability in extreme environments. These lightweight and durable fibers can be processed into various textile forms, such as blankets, boards, papers, ropes, and woven fabrics.

Xcellent Composites' carefully designed insulation ceramic fiber products offer outstanding thermal insulation and low thermal conductivity, making them widely used in industries such as metallurgy, chemical engineering, power generation, and aerospace. Our ceramic fiber cloth and textile is a preferred solution for high-temperature industrial applications due to their durability and versatility. Xcellent Composites continuously seeks technological innovation, dedicated to developing more efficient ceramic fiber products to meet the stringent demands of the global market for advanced refractory materials.

Our Ceramic Fiber Reinforcements

Our Ceramic Fiber Reinforcements

Ceramic Fiber Fabric

Ceramic fiber fabric is notable for its high thermal resistance, capable of withstanding extreme temperatures without significant degradation. It also offers low thermal conductivity, which helps in effective insulation and energy efficiency in various high-temperature applications.

Ceramic Fiber Mat

Xcellent insulation ceramic fiber mat features high thermal insulation properties, providing effective resistance to heat and minimizing energy loss in high-temperature environments. Additionally, it is known for its lightweight nature and flexibility, which facilitate ease of installation and handling in various industrial applications.

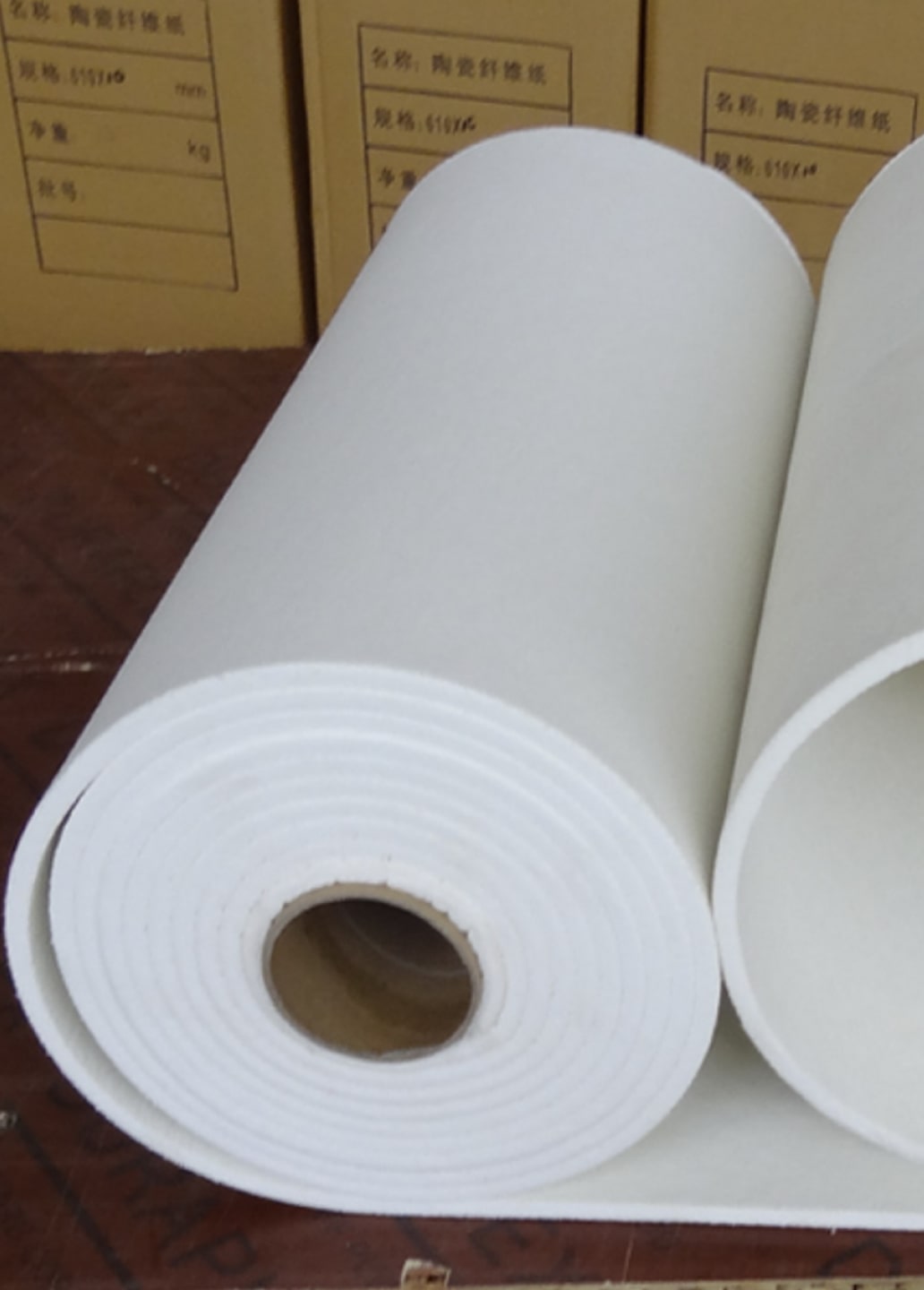

Ceramic Fiber Sheet

Xcellent ceramic fiber sheet is characterized by its high temperature resistance, making it suitable for applications involving extreme heat. It also provides low thermal conductivity, enhancing its effectiveness as an insulating material.

Ceramic Fiber Cord

Xcellent ceramic fiber cord is distinguished by its ability to withstand high temperatures, offering reliable performance in environments exposed to extreme heat. It also features flexibility and durability, making it suitable for sealing and insulation applications where traditional materials may fail.

Ceramic Fiber Tape

Ceramic fiber tape functions primarily as a thermal insulator, providing effective protection against heat transfer in high-temperature environments. It also serves as a sealing material, helping to prevent heat and energy loss in applications where traditional sealing methods may be insufficient.

Ceramic Fiber Sleeve

Ceramic fiber sleeve functions to insulate and protect cables and hoses from extreme heat, thereby maintaining their integrity and performance in high-temperature environments. It also aids in reducing heat transfer and minimizing energy loss by providing a thermal barrier around the enclosed components.

Ceramic Fiber Fabric

Ceramic fiber fabric is notable for its high thermal resistance, capable of withstanding extreme temperatures without significant degradation. It also offers low thermal conductivity, which helps in effective insulation and energy efficiency in various high-temperature applications.

Ceramic Fiber Mat

Xcellent insulation ceramic fiber mat features high thermal insulation properties, providing effective resistance to heat and minimizing energy loss in high-temperature environments. Additionally, it is known for its lightweight nature and flexibility, which facilitate ease of installation and handling in various industrial applications.

Ceramic Fiber Sheet

Xcellent ceramic fiber sheet is characterized by its high temperature resistance, making it suitable for applications involving extreme heat. It also provides low thermal conductivity, enhancing its effectiveness as an insulating material.

Ceramic Fiber Cord

Xcellent ceramic fiber cord is distinguished by its ability to withstand high temperatures, offering reliable performance in environments exposed to extreme heat. It also features flexibility and durability, making it suitable for sealing and insulation applications where traditional materials may fail.

Ceramic Fiber Tape

Ceramic fiber tape functions primarily as a thermal insulator, providing effective protection against heat transfer in high-temperature environments. It also serves as a sealing material, helping to prevent heat and energy loss in applications where traditional sealing methods may be insufficient.

Ceramic Fiber Sleeve

Ceramic fiber sleeve functions to insulate and protect cables and hoses from extreme heat, thereby maintaining their integrity and performance in high-temperature environments. It also aids in reducing heat transfer and minimizing energy loss by providing a thermal barrier around the enclosed components.

Properties of Ceramic Fiber

Properties of Ceramic Fiber

Heat Resistance

Due to factors such as fiber crystallization, grain growth, crystal phase transformation, and impurities' effects on crystallization, as well as the sintering and high-temperature creep at fiber contact points, ceramic fibers may shrink, lose elasticity, become brittle, and even sinter, losing their fibrous structure. Therefore, various types of ceramic fibers have a maximum service temperature, which is internationally classified into four grades: 1000℃, 1260℃, 1400℃, and 1600℃.

Thermal Shock Resistance

Ceramic fibers exhibit excellent thermal shock resistance, attributed to their aggregate structure (entangled fibers with diameters between 2-5μm and a porosity greater than 90%), which makes them soft, elastic, and capable of free elongation in all directions.

Chemical Stability

Ceramic fibers have excellent chemical stability in oxidizing and neutral atmospheres. However, their chemical stability is poor in reducing atmospheres, vacuums, or environments containing sulfates, fluorides, or alkaline metals.

Acoustic Insulation

Ceramic cloth aggregates are porous materials that can be used as sound-absorbing materials. Ceramic fiber products with low bulk density have good sound absorption for high-frequency waves but the opposite for low-frequency waves.

Electrical Insulation

Insulation Ceramic fibers possess excellent electrical insulation properties, which decrease with rising temperatures. However, they still maintain a high dielectric constant and low dielectric loss at elevated temperatures.

Wind Erosion Resistance

Ceramic cloth aggregates are commonly used as high-temperature resistant materials. The introduction of non-woven needling technology in the production of secondary ceramic fiber products has improved the wind erosion resistance of ceramic fiber blankets to 20m/s.

Elasticity and Air Permeability Resistance

When used as sealing or padding materials for high-temperature gases, ceramic fibers cloth should have a certain degree of elasticity and air permeability resistance. As the temperature exceeds 400℃, they will experience some creep, causing a gradual decrease in the rebound resilience of fiber products.

Heat Resistance

Due to factors such as fiber crystallization, grain growth, crystal phase transformation, and impurities' effects on crystallization, as well as the sintering and high-temperature creep at fiber contact points, ceramic fibers may shrink, lose elasticity, become brittle, and even sinter, losing their fibrous structure. Therefore, various types of ceramic fibers have a maximum service temperature, which is internationally classified into four grades: 1000℃, 1260℃, 1400℃, and 1600℃.

Thermal Shock Resistance

Ceramic fibers exhibit excellent thermal shock resistance, attributed to their aggregate structure (entangled fibers with diameters between 2-5μm and a porosity greater than 90%), which makes them soft, elastic, and capable of free elongation in all directions.

Chemical Stability

Ceramic fibers have excellent chemical stability in oxidizing and neutral atmospheres. However, their chemical stability is poor in reducing atmospheres, vacuums, or environments containing sulfates, fluorides, or alkaline metals.

Acoustic Insulation

Ceramic cloth aggregates are porous materials that can be used as sound-absorbing materials. Ceramic fiber products with low bulk density have good sound absorption for high-frequency waves but the opposite for low-frequency waves.

Electrical Insulation

Insulation Ceramic fibers possess excellent electrical insulation properties, which decrease with rising temperatures. However, they still maintain a high dielectric constant and low dielectric loss at elevated temperatures.

Wind Erosion Resistance

Ceramic cloth aggregates are commonly used as high-temperature resistant materials. The introduction of non-woven needling technology in the production of secondary ceramic fiber products has improved the wind erosion resistance of ceramic fiber blankets to 20m/s.

Elasticity and Air Permeability Resistance

When used as sealing or padding materials for high-temperature gases, ceramic fibers cloth should have a certain degree of elasticity and air permeability resistance. As the temperature exceeds 400℃, they will experience some creep, causing a gradual decrease in the rebound resilience of fiber products.

FAQ for Ceramic Fiber

How are ceramic fibers classified by usage temperature?

What are the preparation methods for ceramic fibers?

What are the applications of ceramic fibers in energy saving and environmental protection?

What is insulation ceramic, and what are its primary applications?

How does ceramic fiber material differ from traditional insulation materials?

Can ceramic fiber materials be recycled?

What safety precautions should be taken when handling ceramic fiber cloth?

How do insulation ceramics perform in terms of thermal shock resistance?

Can’t find an answer?

Don't hestitate to contact us

Get Price of Composite Materials

Get Price of Composite Materials

E-mail:

Address:

NO.61, XIANGYANGJIAYUAN, XIAOSHAN, HANGZHOU, CHINA

Composites Knowledge Hub

Composites Knowledge Hub