+86-13732282311

merlin@xcellentcomposites.com

Let the world benefit from composite materials!

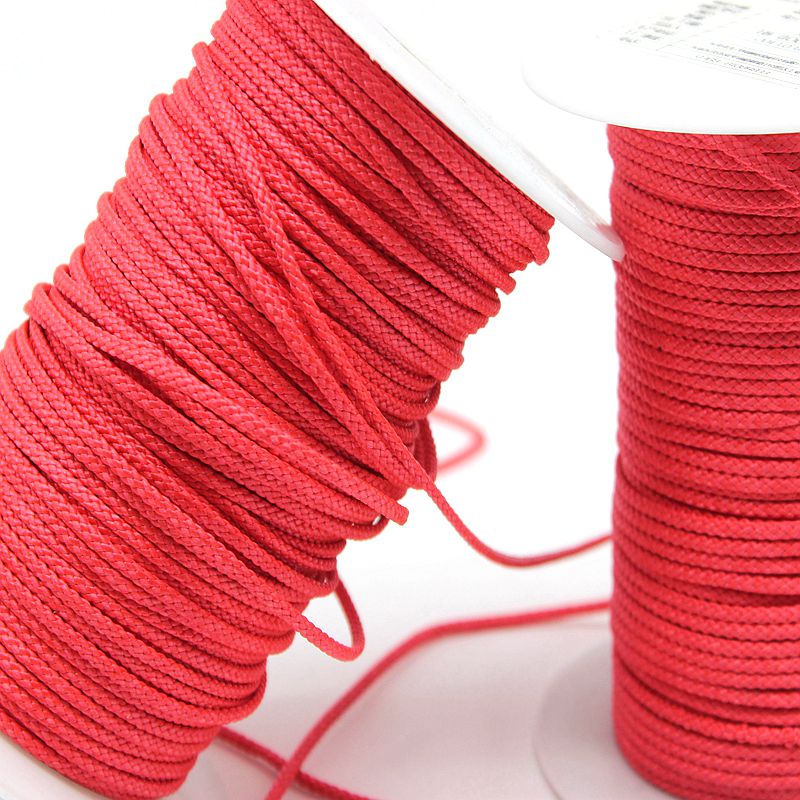

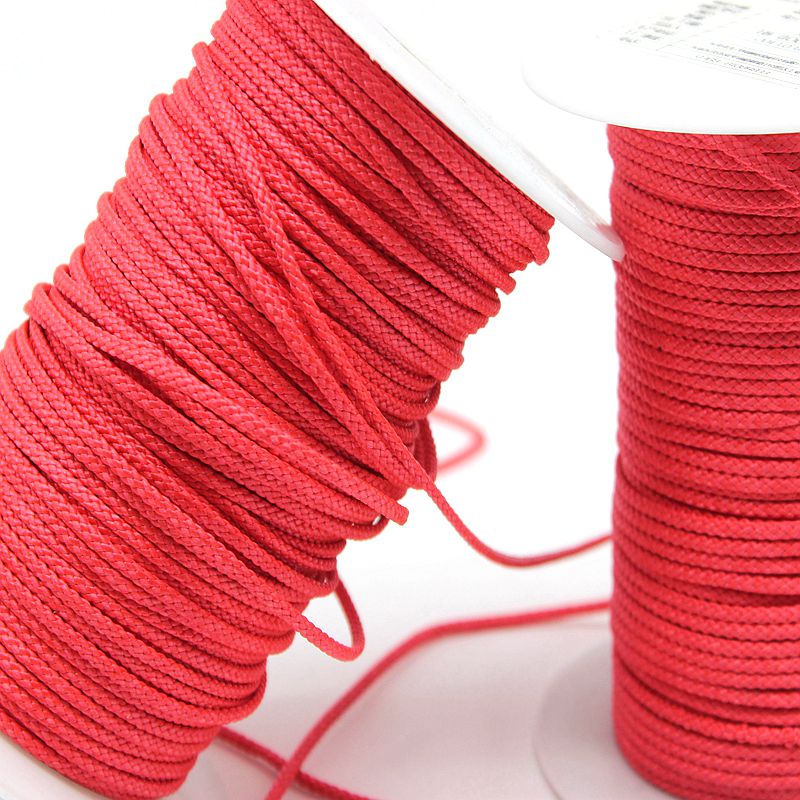

UHMWPE Rope & Cord

Features of UHMWPE Rope & Cord

| 01. | Exceptional Strength: | UHMWPE rope is several times stronger than steel rope of the same weight, yet it weighs only about one-eighth as much. |

| 02. | Durability and Tear Resistance: | This rope offers high resistance to wear and tear, maintaining performance even in harsh environments. |

| 03. | UV and Chemical Resistance: | UHMWPE is highly resistant to ultraviolet rays and most chemicals, making it suitable for outdoor and chemical environments. |

| 04. | Low Elongation: | Under load, UHMWPE rope exhibits very low elongation, which means it remains stable under tension and load. |

| 05. | Buoyancy: | Due to its lower density than water, UHMWPE rope can float, making it ideal for marine and rescue applications. |

Our range of UHMWPE braided cords, UHMWPE ropes, and 12-strand ultra-high molecular weight polyethylene ropes offers superior strength, durability, and versatility for a variety of demanding applications.

Crafted from ultra-high molecular weight polyethylene (UHMWPE), these ropes and cords are exceptionally lightweight while delivering incredible tensile strength, making them ideal for marine, industrial, and outdoor uses. The 12-strand UHMWPE rope features a braided construction that enhances flexibility and load-bearing capacity, ensuring reliable performance under heavy loads.

Whether you need a UHMWPE cord for precise applications or a robust rope for heavy-duty tasks, these products excel in abrasion resistance, UV stability, and minimal stretch, making them the preferred choice for professionals who demand top-quality materials. Choose UHMWPE for strength you can rely on, even in the most challenging conditions.

Get Price of Composite Materials

Get Price of Composite Materials

E-mail:

Address:

NO.61, XIANGYANGJIAYUAN, XIAOSHAN, HANGZHOU, CHINA

Related Composite Materials

Related Composite Materials

Carbon Fiber Spread Tow Fabric

Spread tow fabric is a fabric woven using spread yarn and is a new type of carbon fiber reinforced material. This fabric has characteristics such as low yarn bending, low surface density, good lay-flat properties, and high design flexibility.

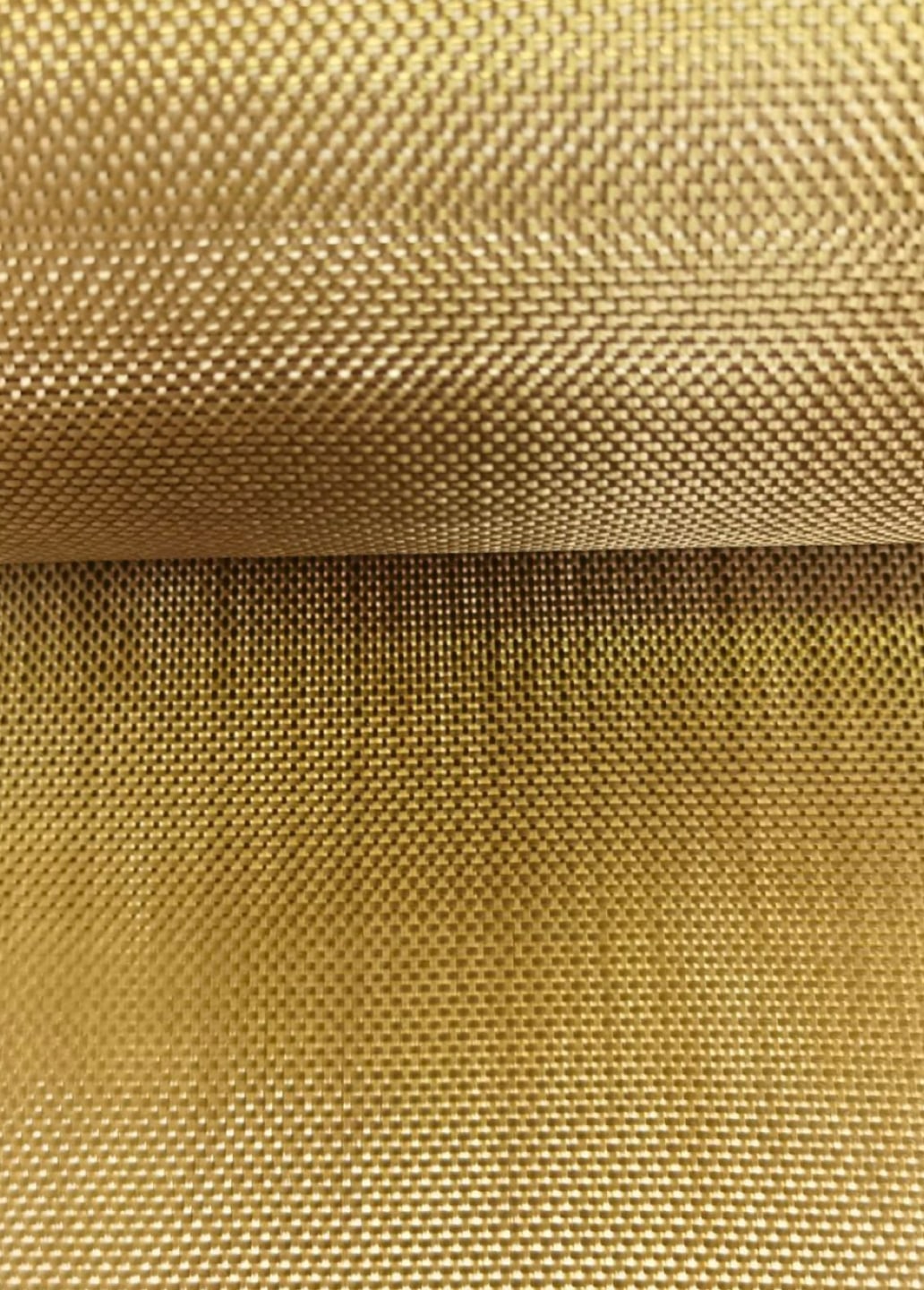

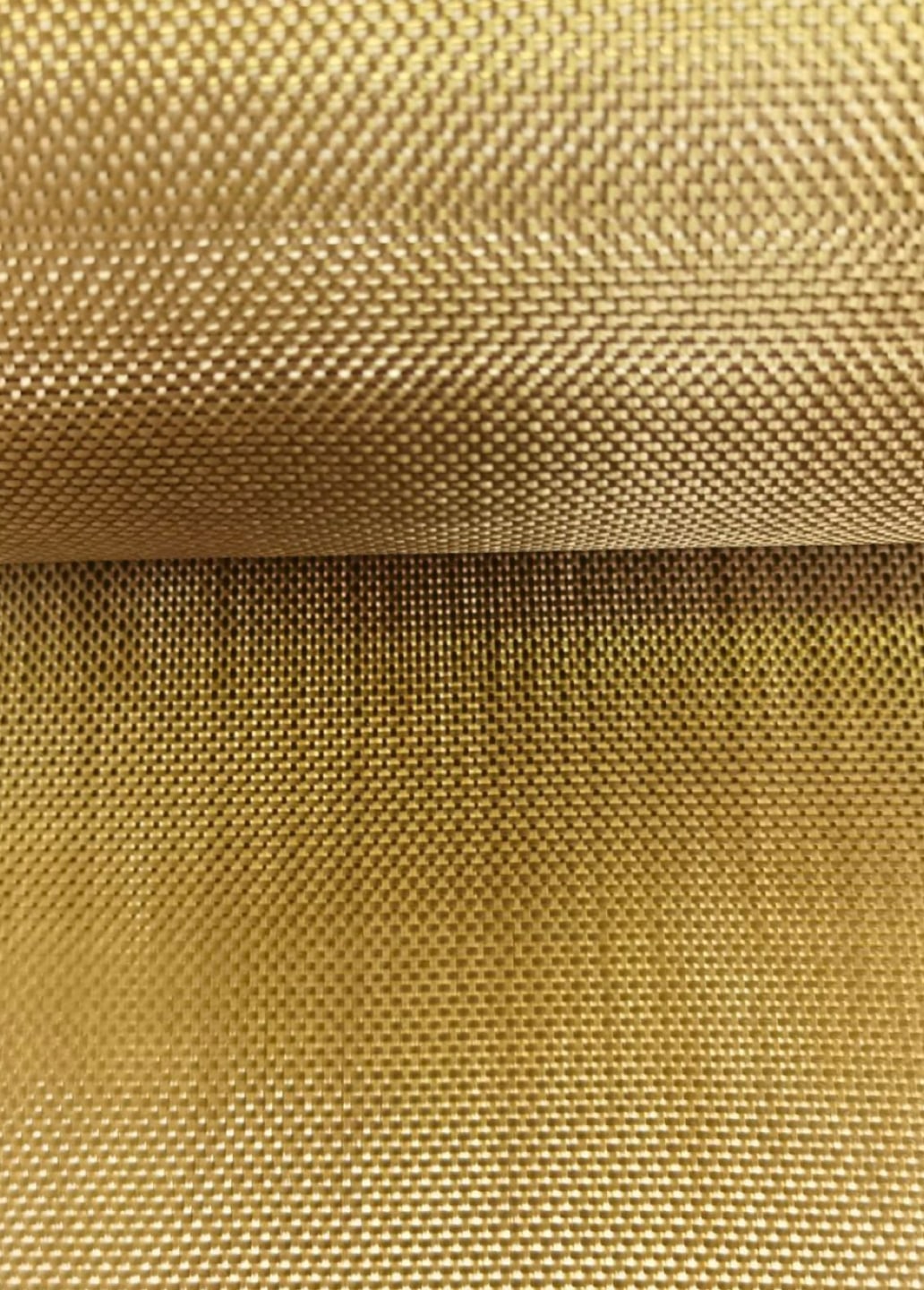

1414 Aramid Fiber Woven Fabrics

Xcellent Composites produces aramid fabrics primarily using para-aramid 1414, and can design them into various fabric structures such as plain, twill, or satin weave, as well as more complex weaving patterns to adjust their mechanical properties and aesthetic characteristics.

Fiberglass Woven Fabric

Xcellent Composites produces a series of fiberglass woven fabrics designed for various applications, including fabrics for electronic printed circuit boards, expansion fabrics, and filter fabrics.

Basalt Fiber Woven Fabric

Basalt mesh fabric is made by twisting basalt fibers and then applying a resin coating. The mesh structure enhances the fabric's stability and durability, making it suitable for reinforcing concrete and road repairs.

Carbon Fiber Spread Tow Fabric

Spread tow fabric is a fabric woven using spread yarn and is a new type of carbon fiber reinforced material. This fabric has characteristics such as low yarn bending, low surface density, good lay-flat properties, and high design flexibility.

1414 Aramid Fiber Woven Fabrics

Xcellent Composites produces aramid fabrics primarily using para-aramid 1414, and can design them into various fabric structures such as plain, twill, or satin weave, as well as more complex weaving patterns to adjust their mechanical properties and aesthetic characteristics.

Fiberglass Woven Fabric

Xcellent Composites produces a series of fiberglass woven fabrics designed for various applications, including fabrics for electronic printed circuit boards, expansion fabrics, and filter fabrics.

Basalt Fiber Woven Fabric

Basalt mesh fabric is made by twisting basalt fibers and then applying a resin coating. The mesh structure enhances the fabric's stability and durability, making it suitable for reinforcing concrete and road repairs.

Composites Knowledge Hub

Composites Knowledge Hub